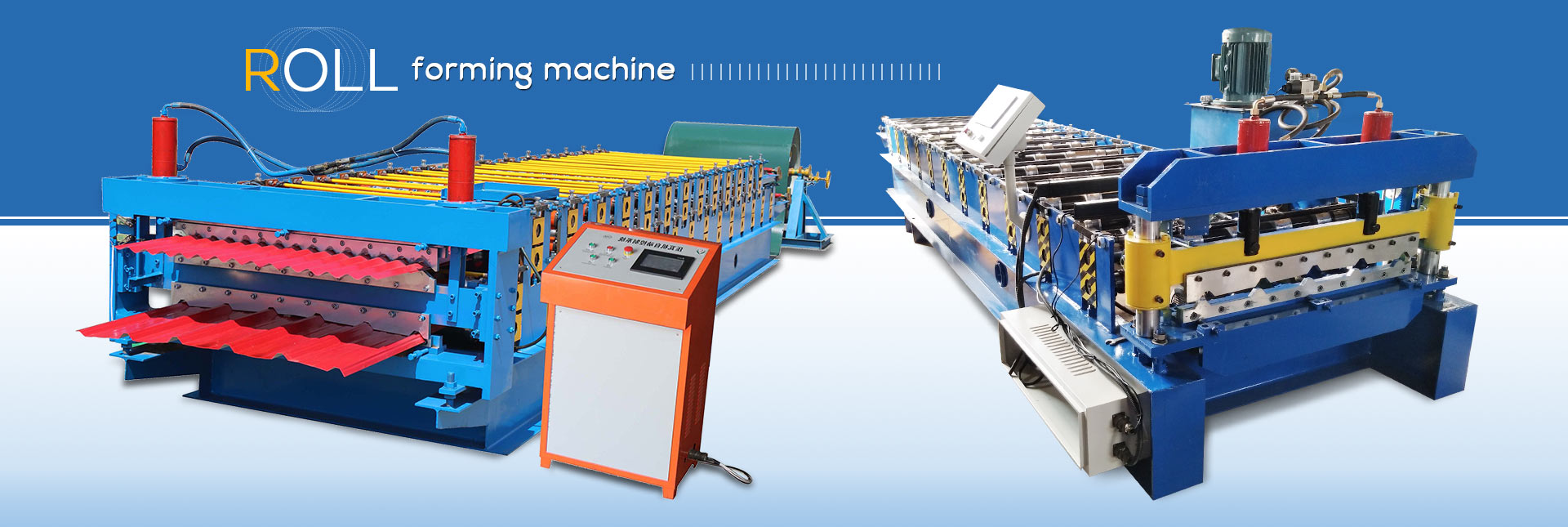

Our Products

Browse our new products below

About Us

Text about our company

WORKING SINCE 1996

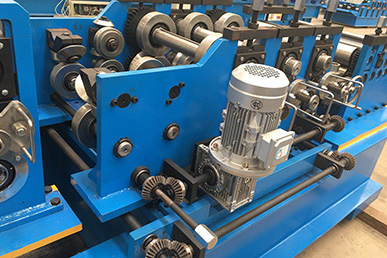

Haixing Industrial Group Co., Ltd. was established in 1996 and is located in Hedong District, Tianjin. It is a professional cold forming machine manufacturer and exporter with over 20 years of experience.

Our products include roof roll forming machines, Leveling and shearing machines, decoilers, c&z purlin roll forming machines, slitting lines, Light steel keel roll forming machines and other associated equipment.

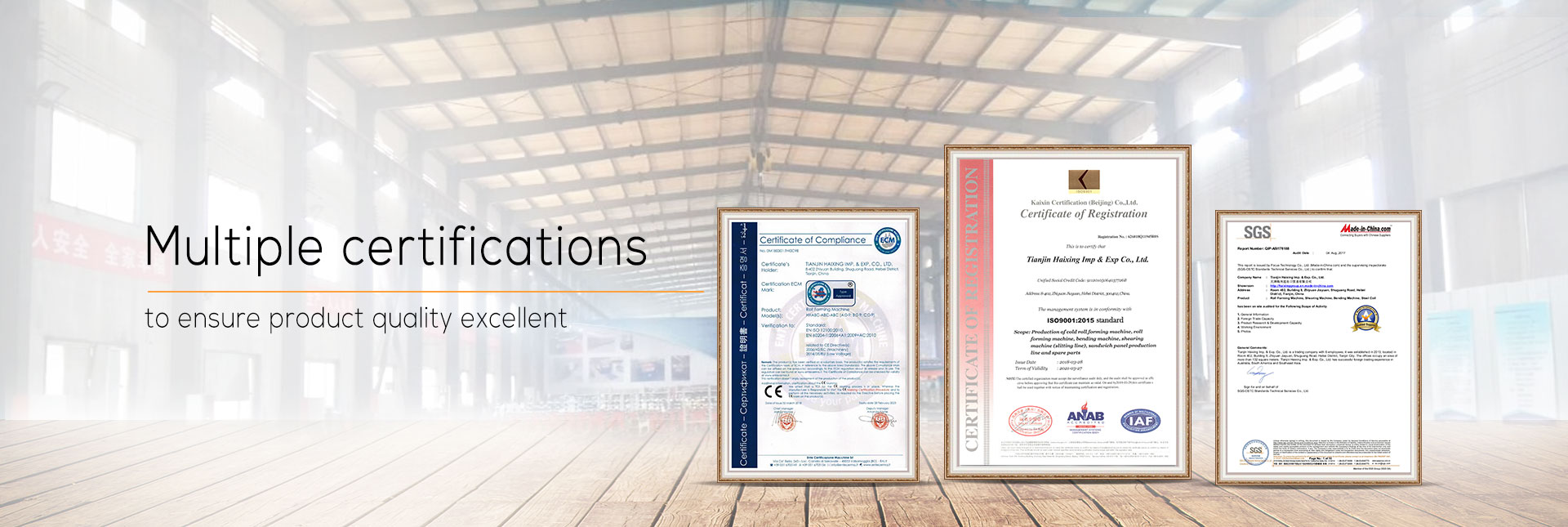

All products comply with international quality standards and are greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on.

Advantages

We are excellent manufacturers

We Are Trusted

Our regular customers

Don't know which machine and raw materials to choose?

Come, we will provide you with the most professional advice and best service!

latest news

new double layer roof machine is ready

new double layer roof machine is ready We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Supply OEM/ODM Doubl...