It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We’re seeking forward in your check out for joint development for Wholesale Price China China Botou Kxd Ridge Cap Roll Forming Machine with Low Price, Since establishment during the early 1990s, we have now create our sale network in USA, Germany, Asia, and several Middle Eastern countries. We aim to be a top class supplier for globally OEM and aftermarket!

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We’re seeking forward in your check out for joint development for China Roll Forming Machine, Ridge Cap Forming Machine, Item have passed by means of the national qualified certification and been well received in our main industry. Our pro engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you’ll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

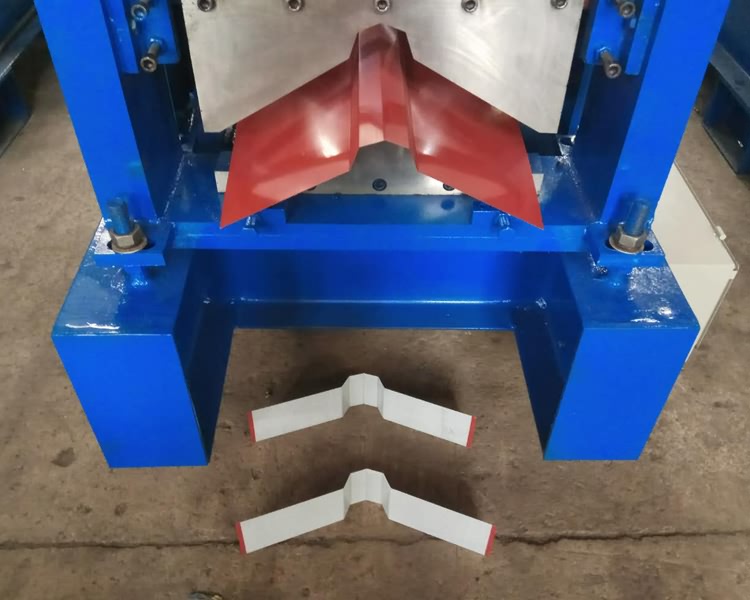

We can manufacture and design various color steel ridge cap roll forming machines according to customer requirements.

|

Color Steel Ridge Cap roll Forming Machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

Machine details:

Contact details

If you have any needs or questions, please feel free to contact us. We will be waiting for you here 24 hours. Please join us.

-

High Quality for Willing Color Steel Roofing Sh...

-

Short Lead Time for Automatic Punching Twist C/...

-

ODM Manufacturer Corrugated Iron Roof Sheet Rol...

-

China Manufacturer for Low Plc Controlled Multi...

-

Manufactur standard Low Rolling Up Cold Steel I...

-

Competitive Price for China Kexinda Stoving Var...