We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Wholesale Price Aluminum Roof Sheet Roll Forming Machine, We sincerely hope to establish some satisfactory relationships with you in the near future. We will keep you informed of our progress and look forward to building steady business relations with you.

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Aluminum Roll Forming Machine, Aluminum Roof Roll Forming Machine, Aluminum Sheet Roll Forming Machineing Machine, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We’ve been specialized in producing.Now we have rich experience in export. Welcome to contact us and your enquiry are going to be replied as soon as possible.

This type of trapezoidal roofing roll forming machine is very popular in Georgia, and its color steel tile has a good quality and beautiful appearance. It is a very worthwhile roll forming machine. The automatic control system of the whole unit of the tile press adopts a highly integrated network to make the performance of the automation system superior.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1200mm |

| 12 | Effective width | 1160mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

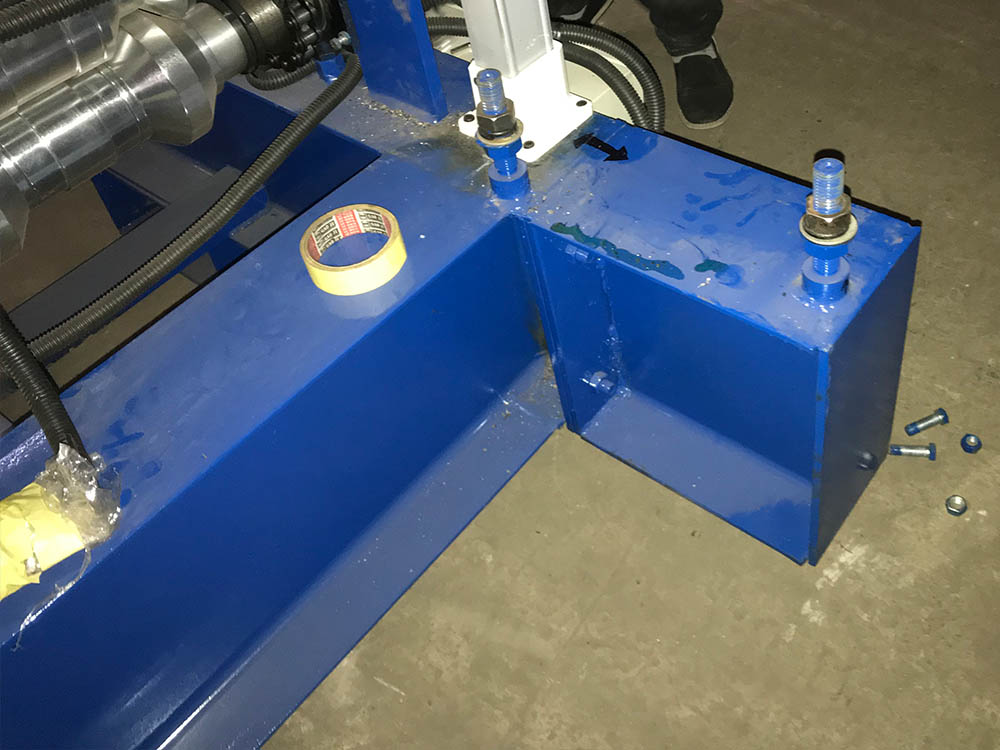

Machine details

Machine package and shipment details

Standard export packing: 1*40 GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

The advantages of automatic roofing sheet roll forming machine:

1.Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2.Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable,maintenance-free.

3.We can make and design will kinds of roll forming machine according to customer’s request.