We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for Wholesale OEM/ODM China 2020 Hot Sell 836 Corrugated Roof Sheet Roll Forming Machine for Guyana Arc Color Steel Glazed Tile Roll Forming Machine, Welcome to go to our firm and manufacturing facility. You should truly feel no cost to get in touch with us if you need any further assistance.

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for China Roll Forming Machine, Corrugated Forming Machine, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

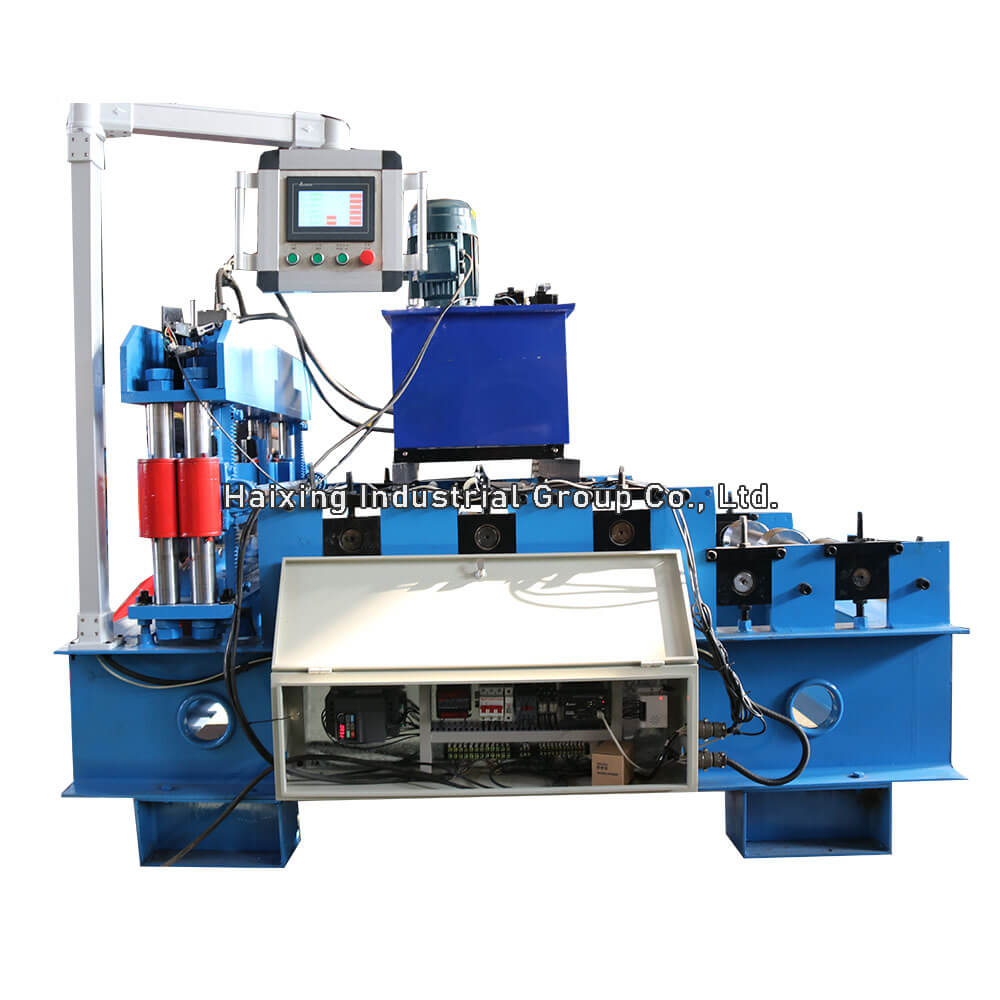

no girder arch roof forming machine parameters

| Main frame | Welded from 350mm H-beam. |

| Roller shaft diameter | 70mm, solid shaft with retaining pad |

| shaft material | 45# steel chrome 0.03mm |

| Transfer method | 1.0 inch chain |

| Medium plate thickness | 16mm |

| Main motor | 3kw, Siemens Bede Motor |

| Hydraulic power station | 4kw, gear pump: Shanghai Lichao |

| Cutter material | Cr12, heat treatment HR50-60 |

| Cutting method | Hydraulic four-column cutting |

| Length tolerance | ±2mm |

| PLC |

High-precision computer control cabinet: Taiwan Delta; touch screen, frequency converter: Mitsubishi |

| Production speed | 1.5-3 m/min |

| Voltage | 380V, three-phase, 50 Hz |

| Feed width | 914mm or or according to customer requirements |

| Number of rows | 3 rows |

| Equipment size | 6500*1350*1400mm |

| Pressing mold material | Cr12 |

| Raw material thickness | 0.28~0.8mm |

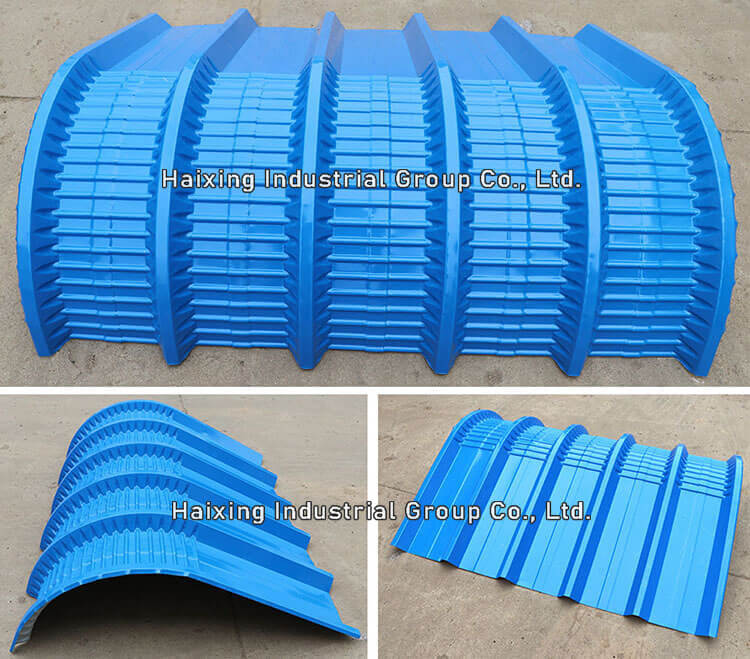

no girder arch roof forming machine pictures

Packing & Shipping

a.The main body of no girder arch roof forming machine with water-proof plastic, then fixed to container by 8mm diameter steel wire and angle iron.

b.Rollers and shafts are covered with anti-rust oil.

c.PLC control system and motor pump are packed with waterproof paper and plastic film.

d.Spare parts in a carton box.

e.Manual decoiler was nude packing.

f.The output-table put into a carton box.

g.If the machine is too long, we will divide it into two parts and pack them in one package with steel wire.

h.Fit for ocean shipping.

-

1080mm design trapezoid roof tile making machine

-

building metal trapezoidal roof rool making mac...

-

C Light Steel Keel Roll Forming Machines

-

Color Steel Glazed Tiles Roof Panel Making Machine

-

10 Ton Hydraulic Decoiler With Coil Car

-

201 Steel Cold Roll Stainless Aluminum Coil

-

4 Meters Hydraulic Roof Sheet Bending Machine

-

6m Steel Bending Machine

-

762 Corrugated Roof Metal Sheet Roll Forming Ma...

-

988 Corrugated Roof Roll Forming Machine

-

Advanced Cnc Hydraulic Metal Sheet Shearing Mac...