Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of Wholesale ODM Xh13-65-850 Corrugated Steel Roof Panel Forming Machine, Leading the trend of this field is our persistent intention. Furnishing to start with class items is our aim. To create a beautiful future, we would want to cooperate with all good friends at your home and overseas. Should you’ve any interest inside our solutions, please will not wait to get in touch with us.

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of Corrugated Steel Roof Panel Forming Machine, Roof Tile Making Machine, Roof Tile Sheet Rolling Forming Machine, Our pro engineering team will generally be prepared to serve you for consultation and feedback. We’re able to also provide you with free of charge samples to meet your requirements. Best efforts will likely be produced to deliver you the best service and merchandise. When you are keen on our business and goods, please speak to us by sending us emails or call us quickly. In an effort to know our goods and company extra, you may come to our factory to view it. We are going to generally welcome guests from all over the world to our business to create business relations with us. Make sure you feel cost-free to speak to us for small business and we believe we are going to share the best trading experience with all our merchants.

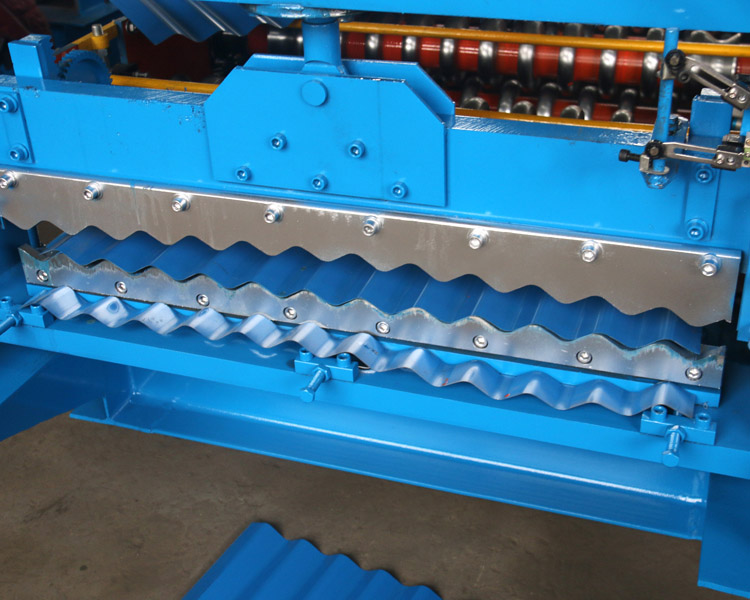

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.