We try for excellence, services the customers”, hopes to become the ideal cooperation team and dominator company for staff, suppliers and buyers, realizes value share and continuous marketing for Wholesale ODM Pressure Polyurethane Spray Foam Machine, For further queries or should you have any question regarding our products, please do not hesitate to contact us.

We try for excellence, services the customers”, hopes to become the ideal cooperation team and dominator company for staff, suppliers and buyers, realizes value share and continuous marketing for Polyurethane Foam Making Machine, Polyurethane Spray Foam Machine, Pu Foam Machine, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

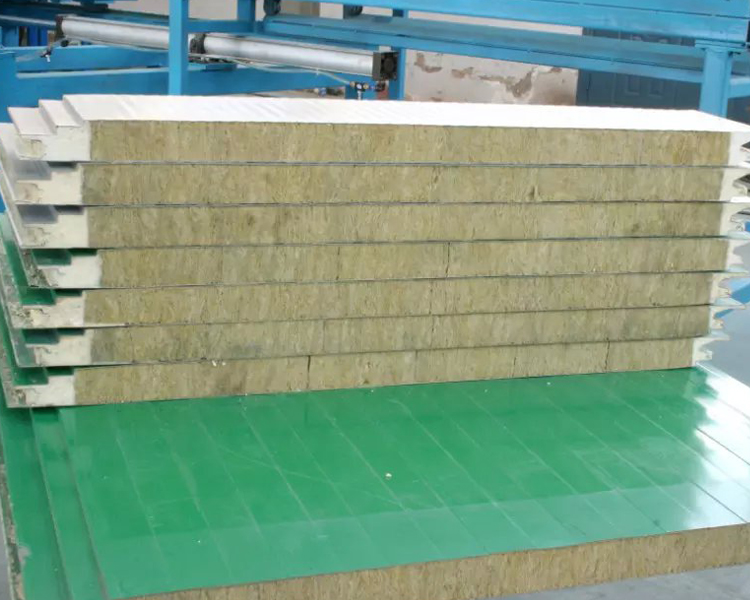

PU Sandwich panel as a kind of construction material is widely used in construction, heat preservation, packaging, frozen, daily necessities, industrial casting, etc.

It can also be used to display the assembly places, commodity cabinet, signs and toys manufacture.

|

PU Sandwich Roof Roll Forming Machine parameters |

||

|

1 |

Equipment overall dimensions |

30m*2.6m*3m |

|

2 |

Total weight |

About 16 ton |

|

3 |

Control system |

Omron encoder PLC |

|

4 |

Main motor power |

Planetary cycloid reducer, 4kw, 380V, 50HZ |

|

5 |

Processing speed |

4~4.5 m/min, continuous stepless adjusted, variable frequency speed regulation, digital display |

|

6 |

raw material |

1.2 meters |

|

7 |

Voltage |

380V |

|

8 |

Roller material |

chrome plated on 45# steel forgings |

|

9 |

Number of rubber shafts |

27 foams, 39 rock wool |

|

10 |

Total power |

30 kw |

|

11 |

Synchronous controller |

Digital synchronous controller |

|

12 |

Corrugated press motor power |

Double-stage cycloid reducer 4kw, 380V, 50HZ |

|

13 |

Application |

roof panel, wall panel |

Machine picture display

Packaging and Shipping

1) Tighten the container with a wire rope and weld the container to the container with natural iron.

2) Main forming machine and un-coiler is naked (we can also use waterproof plastic packaging if needed).

3) PLC control system and motor pump are packed in wooden box with water proof paper coverage.

-

Factory made hot-sale Roller Shutter Door Roll ...

-

OEM/ODM Manufacturer China Bemo Standing Seam R...

-

Factory Price Low Metal Double Layer Steel Roof...

-

Wholesale China Light Steel Keel Stud and Track...

-

Best quality Manufacture Sells Dw89nc Hydraulic...

-

Factory Cheap Ibr Metal Roof Sheet Tile Making ...