So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Wholesale ODM Metal Roofing Galvanized Aluminum Corrugated Steel Sheet Making Machine Colored Steel Wall Roof Panel Cold Roll Forming Machine, We’re not contented with the present achievements but we have been trying ideal to innovate to meet buyer’s much more personalized needs. No matter where you will be from, we’re here to wait for your type ask for, and welcom to go to our manufacturing unit. Choose us, you can fulfill your dependable supplier.

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Colored Steel Wall Roof Panel Cold Roll Forming Machine, Metal Roofing Galvanized Aluminum Corrugated Steel Sheet Making Machine, Metal Roofing Galvanized Aluminum Wall Roof Panel Cold Roll Forming Machine, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We’ve been able to also give you with no cost samples to meet your needs. Best efforts will likely be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and solutions and enterprise. lot more, you’ll be able to come to our factory to find out it. We’ll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should actually feel absolutely free to make contact with us for small business and we believe we’ll share the top trading practical experience with all our merchants.

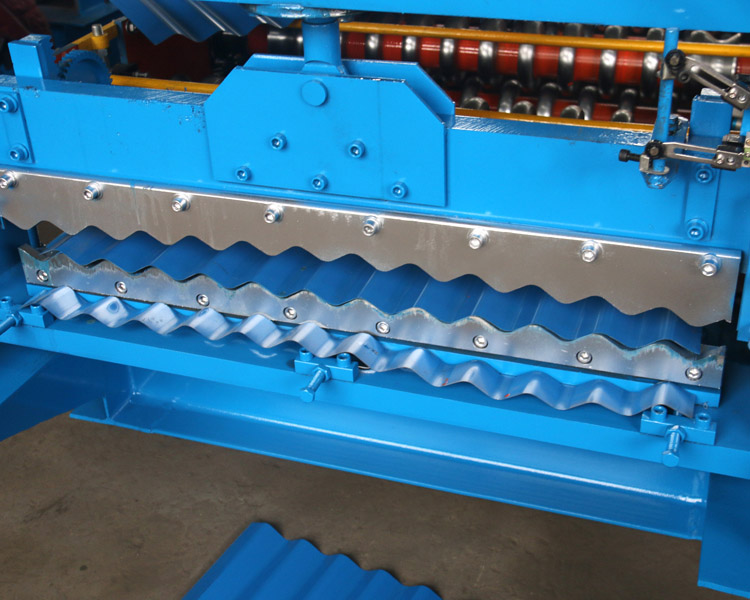

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

New Delivery for China Xiamen Liming Brand 1.5t...

-

High reputation Product Full-automation C U Sha...

-

Manufacturer for Metal Stud Ceiling Light Steel...

-

Chinese wholesale Plc Control System Available ...

-

Factory best selling C Z Interchangeable Used C...

-

Cheap price Metal C Shape Furred Ceil Studs Tra...