It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for Wholesale Dealers of China Tile Production Line Ibr Roof Roll Forming Machine, To acquire a consistent, profitable, and constant growth by getting a competitive advantage, and by continuously increasing the value added to our shareholders and our employee.

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for China Metal Roof Ridge Cap Machine, Ridge Cap Making Machine, Our expert engineering group will always be ready to serve you for consultation and feedback. We’ve been able to also provide you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and items. For anyone who is thinking about our company and merchandise, you should contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We’ll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we have been planning to share the top trading practical experience with all our merchants.

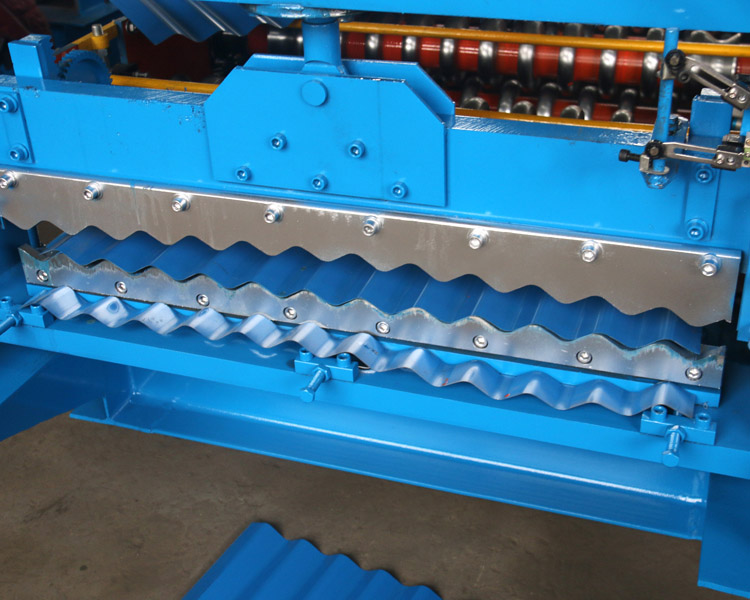

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Massive Selection for Corrugated Metal Roofing ...

-

Special Design for China Light Steel Keel Drywa...

-

Top Grade Used Roll Forming Machine Light Keel ...

-

Free sample for 380v Construction Machinery Sma...

-

cr high speed steel coil slitting line sheet me...

-

New Arrival China Double Layer Corrugated Roof ...