Well-designed Light Steel Keel Roll Forming Machine - China OEM Namibia Ibr 686 Roof Sheet Roll Forming Machine – Haixing Industrial Detail:

Which has a complete scientific excellent management technique, excellent quality and very good religion, we earn good name and occupied this field for China OEM Namibia Ibr 686 Roof Sheet Roll Forming Machine, We sincerely welcome overseas buyers to consult for that long-term cooperation as well as the mutual progress.

Which has a complete scientific excellent management technique, excellent quality and very good religion, we earn good name and occupied this field for Ibr 686 Roof Sheet Machine, Namibia Ibr 686 Rolling Machine, Sheet Roll Forming Machine, We’ve been your reliable partner in international markets with the best quality items. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade merchandise in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

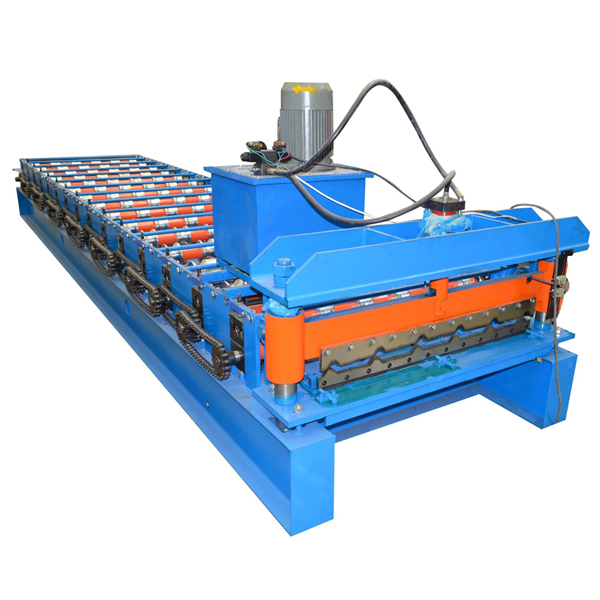

IBR roof sheets made of IBR roof panel roll forming machines generally refers to a profiled tile of an effective width of 686.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm or 940mm |

| 12 | Effective width | 686mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

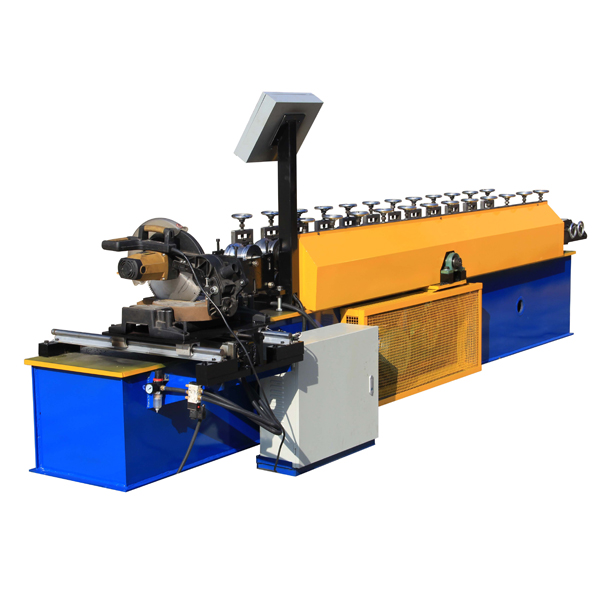

Machine picture display

Packaging Details:

1. machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

7 Steps to Safer, Stronger Decks | Ibr Roof Sheet Making Machine

HOUSING CRISIS sets up ballot battle on RENT CONTROL — TRUMP’s car, ag policies continue to divide — ALLEN finally endorses COX for governor — FIRES continue to scorch | Floor Deck Macking Machine

Well-designed Light Steel Keel Roll Forming Machine - China OEM Namibia Ibr 686 Roof Sheet Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Manufacturing Companies for Roll Form Machine R...

-

Factory Cheap Steel Half Round Waterdown Gutter...

-

Hot Sale for 2 Arms Fume Extractor - Color Coa...

-

Renewable Design for Steel Plate Transverse Cut...

-

Good quality W Beam Highway Guardrail Machine -...

-

High reputation Metal Rain Gutter Roof Roll For...