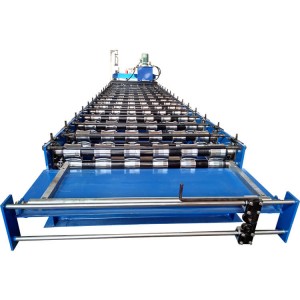

Quick detail of u section purlin roll forming machine

| 1 |

manual decoiler |

Manual tension, passive put coil |

| 2 |

decoiler max put weight |

3T |

| 3 |

Machine Frame |

400 H-beam welding with middle plate 20mm |

| 4 |

Forming machine-oriented feed rack type |

Lateral wheel type |

| 5 |

Forming machine type |

Wall panel chain drive Direct guide rail size |

| 6 |

Shaft Diameter |

80mm solid |

| 7 |

Transfer method |

Hydraulic motor/Reducer motor |

| 8 |

Production Line Speed |

25m/8m/min |

| 9 |

Rollers number |

7 roll leveling 15 rows forming |

| 10 |

Roll material |

Bearing steel vacuum quenching |

| 11 |

Quenched treatment |

HRC58°-60 |

| 12 |

Main motor power |

Change type of motor 3*1.5KW, Motor pump station 11.5KW |

| 13 |

Hydraulic station motor |

Gear pump |

| 14 |

Cutting way |

Hydraulic stepless shear, the hole set arbitrarily |

| 15 |

Materials thickness |

1.0mm-3.0mm |

| 16 |

Length Tolerance |

±2mm |

| 17 |

Control system |

PLC control |

U section purlin roll forming machine has good compressive strength and flatness; automatic measurement, cutting and punching; highly automated and easy to install.

U section purlin roll forming machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Previous: Automatic CZ interchange purlin machine

Next: Z Purlin Channel Roll Forming Machine