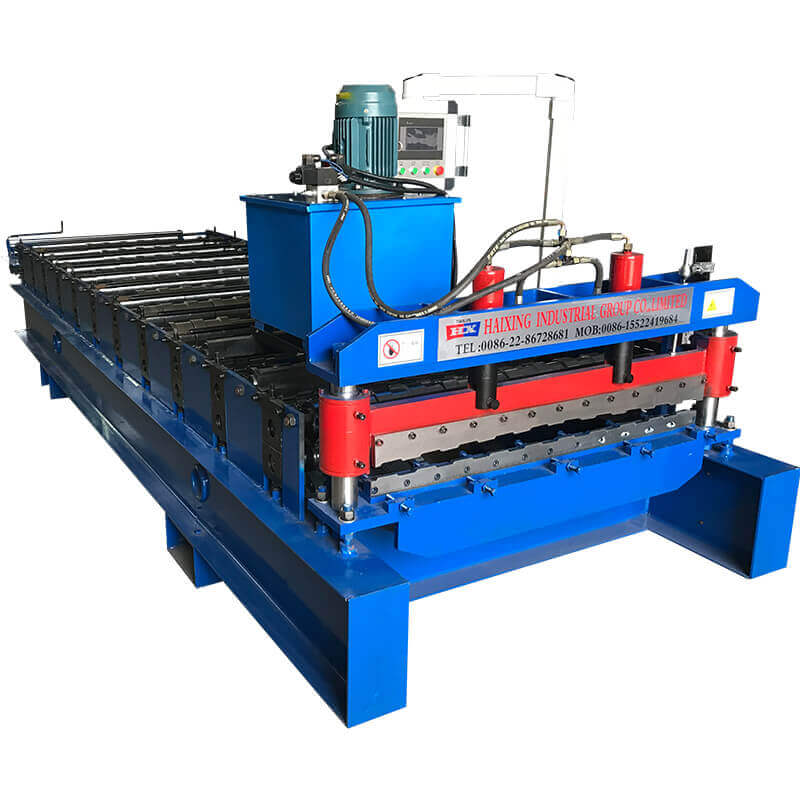

Trapezoidal sheet roof wall panel machine parameters

| Hydraulic pressure | 10-12MPa according to oil pump and pump motor | Main motor power | 4/5.5/7.5KW or as actual demands |

| Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) | Hydraulic motor power | 3/4/5.5KW or as actual demands |

| Main frame | 350/400H beams according to machine demands | Control system | Automatic PLC control system |

| Wall sheet thickness | 16/18/20/22mm according to machine demands | Feeding thickness | 0.3-0.8 mm |

| Feeding material | Galvanized steel coil/color steel coil/aluminum steel coil | Roller material | 45# steel |

| Productivity | 0 – 25m/min (according to machine specification) | Cutter material | Cr12MOV |

| Roll station | Common 11 or 25rolls (according to different design) | Cr-plating size | 0.05 mm |

| Roller diameter | 70/75/80mm (depends on different design) | Chain size | 1/1.2inch according to machine demands |

Main details of Trapezoidal sheet roof wall panel machine

We offer our customers easy-broken parts for free.

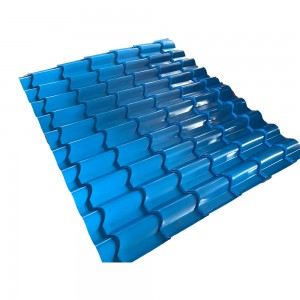

Application

Roof roll forming machinery could produce metallic roofing tile, trapezoidal or sinusoidal roofing sheet, floor deck, C and Z purlin, expressway guardrail, channel and stud, roller shutter and sandwich panel, etc. Customized profiles and requirements are acceptable, and assistant equipment such as hydraulic decoiler, auto stacker, etc.

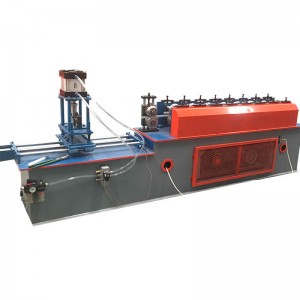

Packaging details

1. Trapezoidal sheet roof wall panel machine are nude packing (If you need, we can also packed it with water-proof plastic).

2. PLC control system and motor pump are packed with waterproof paper, spare parts in a carton box.

3. One set of machine needs a 40′ container to shipping.