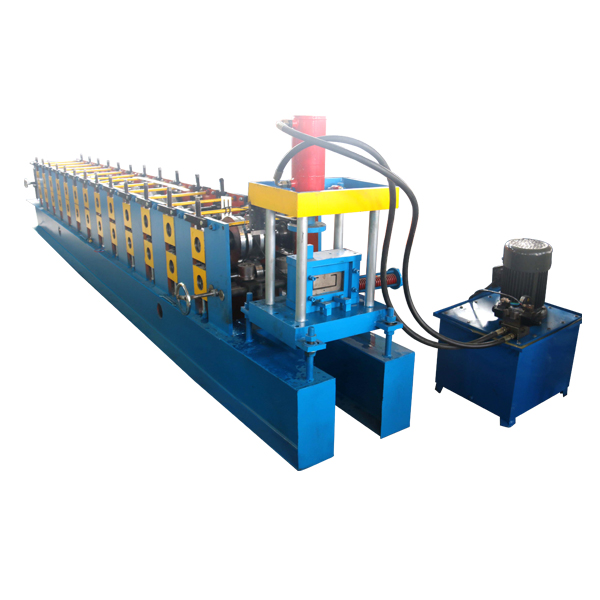

Top Suppliers Steel Foot Pedal Shearing Machine - Corrugated roof and wall panel roll forming machine 850 – Haixing Industrial Detail:

The corrugated roof and wall panel roll forming machine adopts PLC control panel, and its language can be used in English, Spanish, Russian, etc.. Our corrugated roof and wall panel roll forming machine use sensors imported from Mitsubishi, Japan. Other parts are from well-known suppliers in China. This makes our machines have a high quality and long service life.

parameters:

| 1 | Main motor power | 4kW/5.5KW or as actual demands |

| 2 | Hydraulic motor power | 3kW/4KW or as actual demands |

| 3 | Hydraulic pressure | 10-12MPa according oil pump and pump motor |

| 4 | Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) |

| 5 | Control system | Automatic PLC control system |

| 6 | Main frame | 350H beams/400H beams according machine demands |

| 7 | Wall sheet thickness | 16mm/18mm/20mm/22mm according machine demands |

| 8 | Chain size | 1 inch/1.2inch according machine demands |

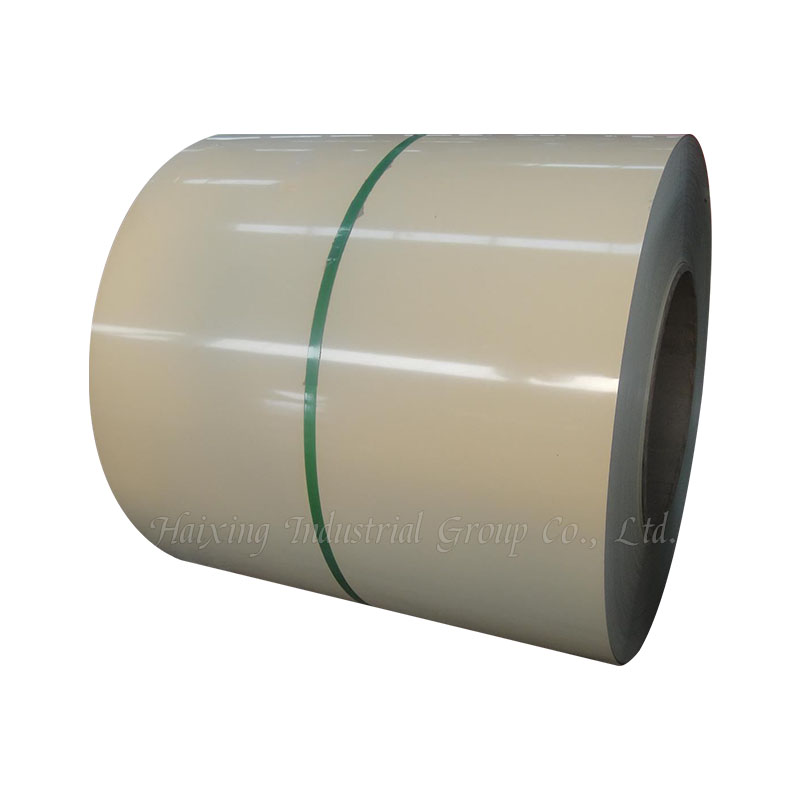

| 9 | Feeding material | Galvanized steel coil/color steel coil/aluminum steel coil |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Productivity | 10 – 25m/min (according machine specification) |

| 12 | Roll station | Common 11rolls ro 25rolls (according to different design) |

| 13 | Roller diameter | 70mm/75mm/80mm (depends on different design) |

| 14 | Roller material | 45# steel |

| 15 | Cutter material | Cr12MOV |

| 16 | Cr-plating size | 0.05 mm |

、

、

Product detail pictures:

Related Product Guide:

Enercon’s EP3 vision takes shape | Roof Sheet Curving Machine

Jeff Bezos’ $2B gift to charity is equivalent to the average US household giving just $1,170 | Steel Downpipe Roll Forming Machine

Top Suppliers Steel Foot Pedal Shearing Machine - Corrugated roof and wall panel roll forming machine 850 – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Original Factory Stud And Track Roll Forming Ma...

-

2017 New Style Clean 2 Arms Fume Extractor - M...

-

Factory directly supply Steel Downspout Roll Fo...

-

Good Wholesale Vendors Metal Straightening Mach...

-

Hot sale Water Gutter Forming Machine - Ceilin...

-

Fixed Competitive Price Downspout Gutter Making...