Top Suppliers Metal Coil Tension Leveling Machine - China Factory for Keel Angle Roll Forming Machine/c Ceiling T Bar Machine/production Line – Haixing Industrial Detail:

The very abundant projects administration experiences and 1 to just one provider model make the higher importance of company communication and our easy understanding of your expectations for China Factory for Keel Angle Roll Forming Machine/c Ceiling T Bar Machine/production Line, Because we stay during this line about 10 years. We got most effective suppliers aid on top quality and selling price. And we had weed out suppliers with poor quality. Now quite a few OEM factories cooperated with us too.

The very abundant projects administration experiences and 1 to just one provider model make the higher importance of company communication and our easy understanding of your expectations for C Ceiling Machine, Ceiling T Bar Production Line, T Bar Machine, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

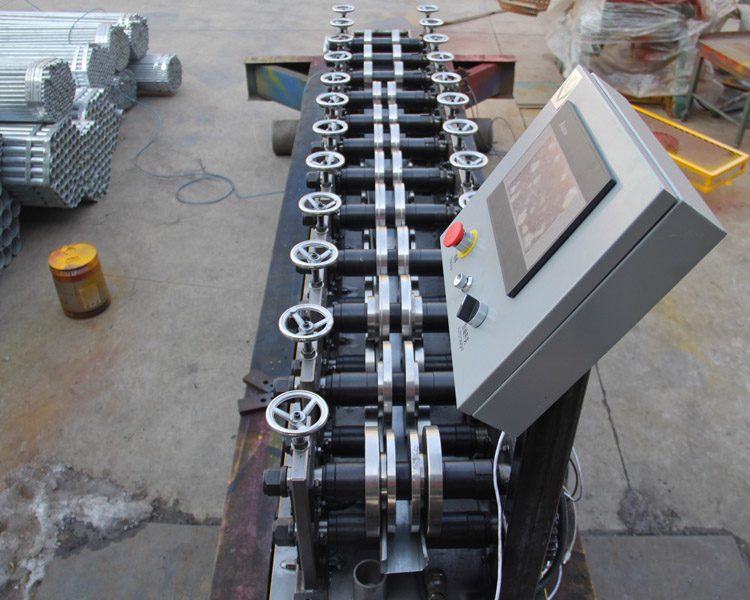

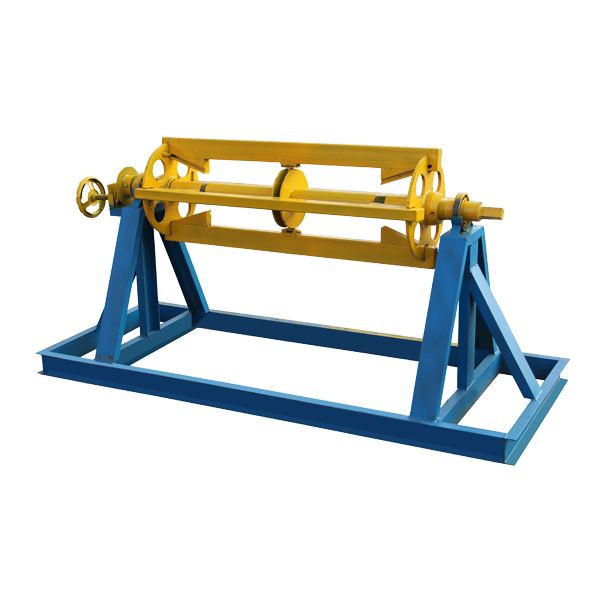

Equipment components of C channel light steel keel making machine:

Manual decoiling, roll forming machine, computer control system, hydraulic control system, cutting, run out table.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

C channel light steel keel roll forming machine picture display

Packaging Details:

1. Machine is covered by plastic film

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Royal Caribbean Symphony of the Seas suites in photos | Roof Sheet Curving Machine

PHOTO: Bear climbs up to 2nd floor deck to eat bird seed | Steel Downpipe Roll Forming Machine

Top Suppliers Metal Coil Tension Leveling Machine - China Factory for Keel Angle Roll Forming Machine/c Ceiling T Bar Machine/production Line – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Hot-selling W Beam Making Roll Forming Machine ...

-

One of Hottest for Used 4-Roll Plate Bending Ma...

-

Factory Cheap Roofing Ridge Cap Cold Roll Formi...

-

High Quality for Galvanized Steel T Grid Making...

-

Leading Manufacturer for Machine For Decoiling ...

-

Manufacturer for C Channel Hole Punching Machin...