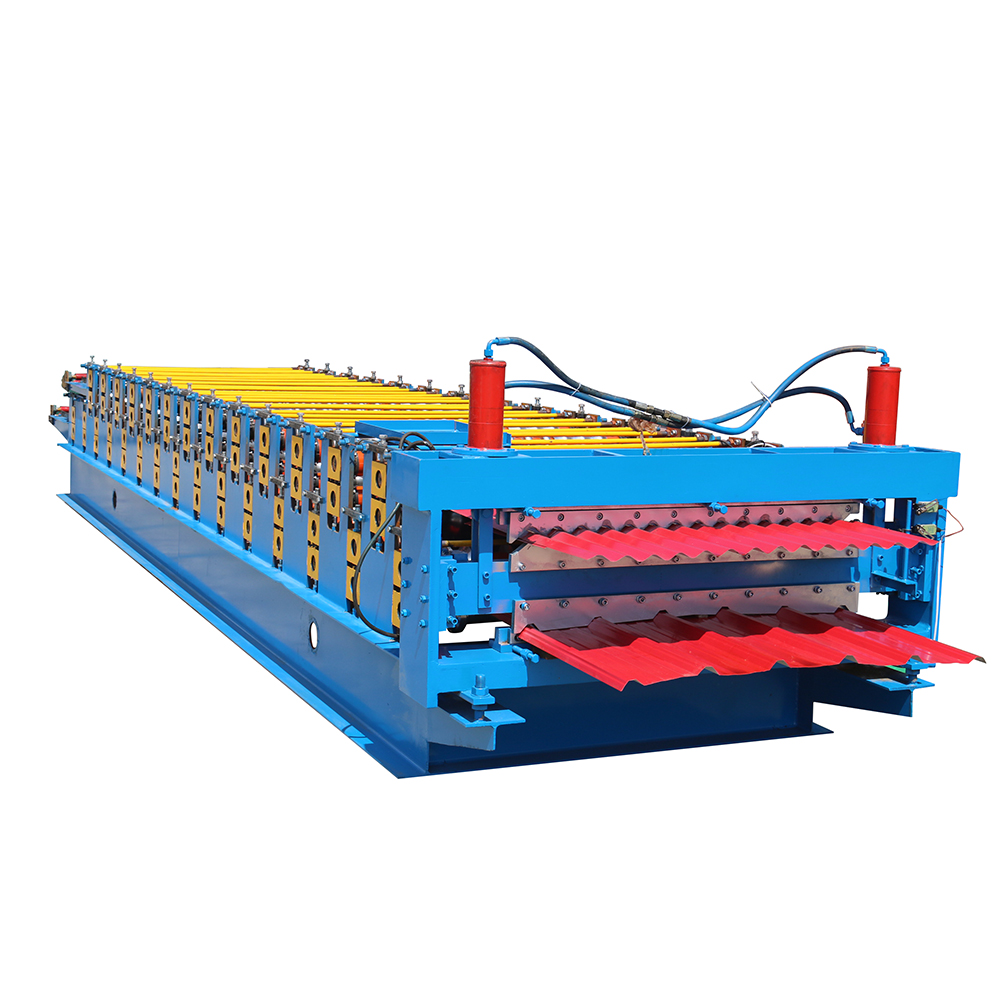

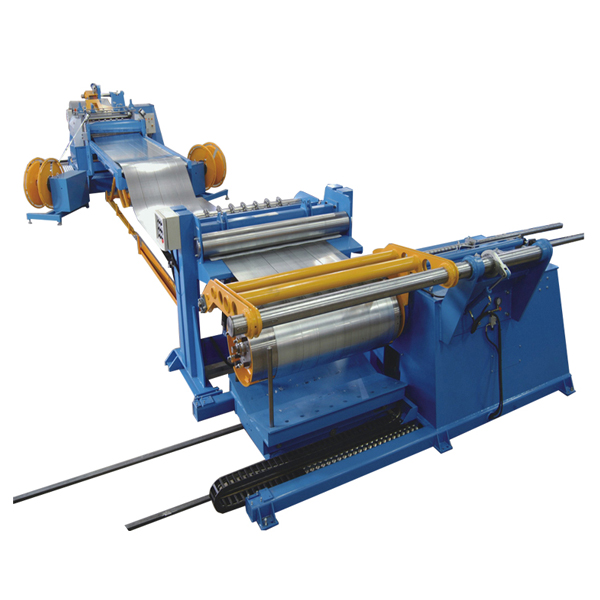

Top Suppliers Automatic Curved Machine - Double Layer Roofing Sheet Roll Machine – Haixing Industrial Detail:

We have a variety of machinery and production methods to meet the growing needs of our customers. Our different types of roll forming operations are simple and efficient.

Parameters of double layer corrugated roof sheet making machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Machine photos

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our machine’s packaging:

1.Main roll forming machine package by Plastic film;

2.Main machine spare parts package by paper box;

3.We have professional technicians for loading, guaranteed the goods load into container without any damage.

Product detail pictures:

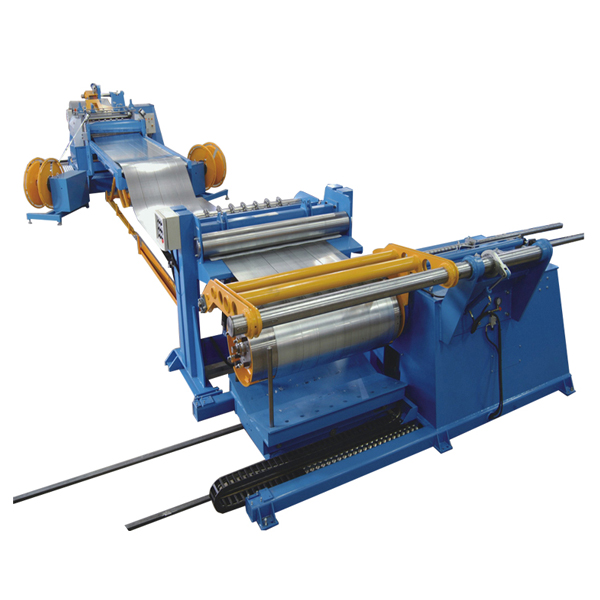

Related Product Guide:

Tried and Tested: Audi RS5 Coupé – Rock Me Gently Tried and Tested: Audi RS5 Coupé | Decoiler In Color Coating Line

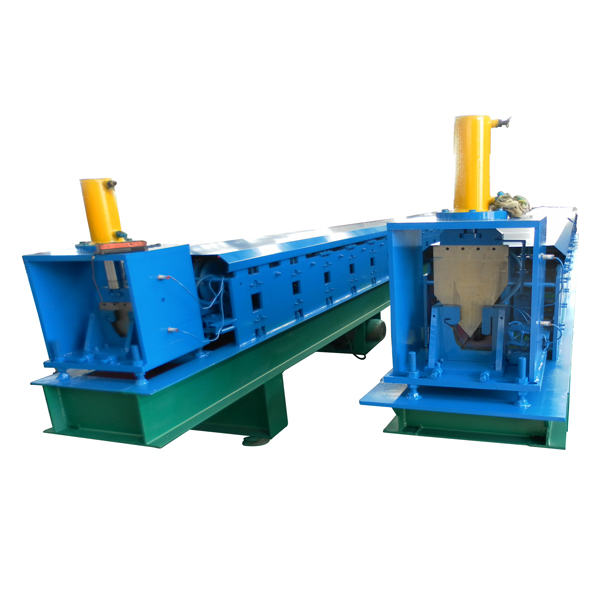

Quip builds out productivity offerings with ‘Slides’ | Steel Downpipe Roll Forming Machine

Top Suppliers Automatic Curved Machine - Double Layer Roofing Sheet Roll Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

High definition Aluminum Profile Bending Machin...

-

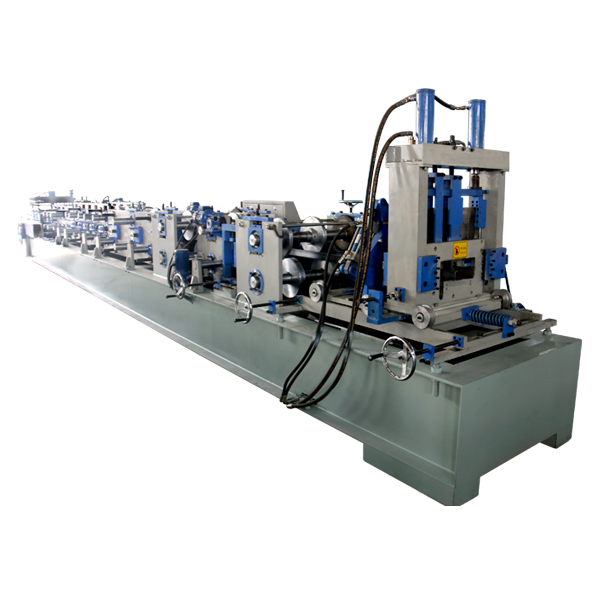

Factory source Bending Aluminum Machine - C Z ...

-

Competitive Price for Interchangeable C Z Purli...

-

18 Years Factory Used Shearing Machine - 10 to...

-

Leading Manufacturer for Soldering Fume Extract...

-

Hot sale Factory Rockwool Sandwich Panel Machin...