Top Quality Downpipe Roll Forming Machine - Galvanized Curving Roof Machine – Haixing Industrial Detail:

|

Galvanized Curving Roof Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

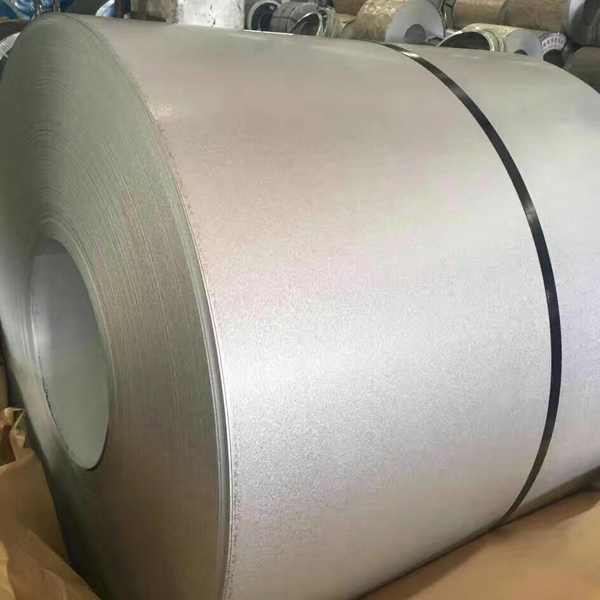

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

The advantages of galvanized curving roof machine:

1. Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2. Controlling by computer, PLC display, operation is easy, running is steady and reliable, endurable, maintenance-free.

3. We can make and designs will kinds of roll forming machine according to customer’s request.

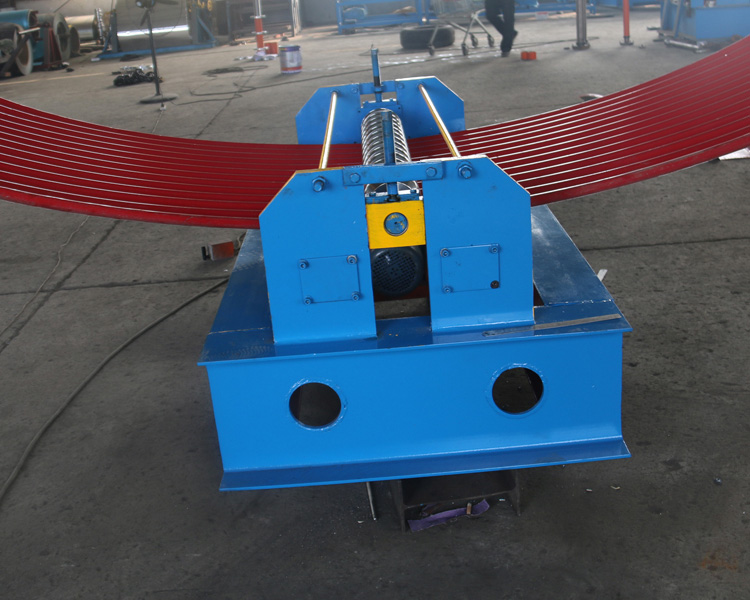

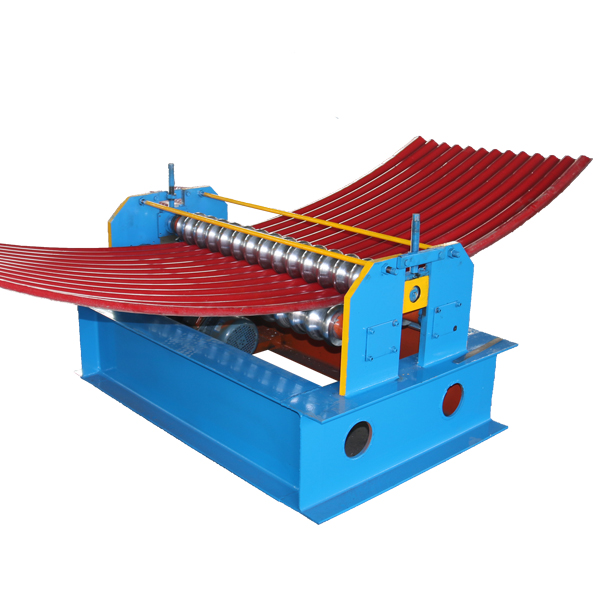

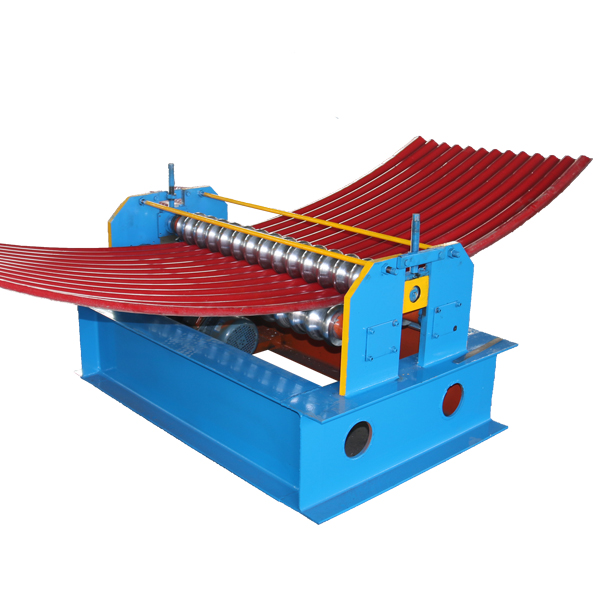

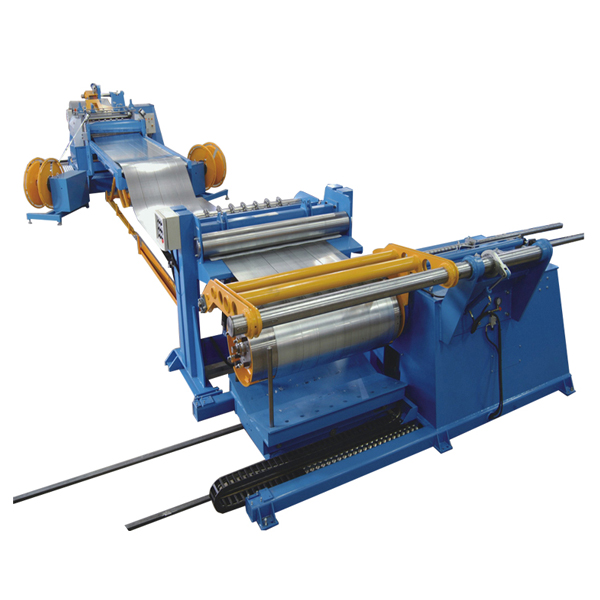

Machine photos:

Product detail pictures:

Related Product Guide:

Newbie designer Stuart Charles Towner on how he made it to Chelsea | Floor Deck Macking Machine

The Top Yachts at the Fort Lauderdale International Boat Show | Steel Downpipe Roll Forming Machine

Top Quality Downpipe Roll Forming Machine - Galvanized Curving Roof Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Cheapest Price Bending Sheet Hydraulic Machine ...

-

OEM China Steel Coil Shearing Machine - Quoted...

-

Personlized Products Round Downpipe Tube Making...

-

Hot-selling W Beam Making Roll Forming Machine ...

-

OEM Supply Pipe Roll Forming Machine - Alumini...

-

Renewable Design for Corrugated Steel Machine -...