The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for Supply OEM/ODM Corrugated Zinc Coated Metal Roof Plate Tile Roll Forming Making Machine, We can do your customized order to meet your own satisfactory! Our company sets up several departments, including production department, sales department, quality control department and sevice center, etc.

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for Corrugated Metal Roofing Sheet Machine, Roll Forming Machine, Roof Plate Sheet Corrugated Roll Forming Machine, After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our items are welcomed all over the world.

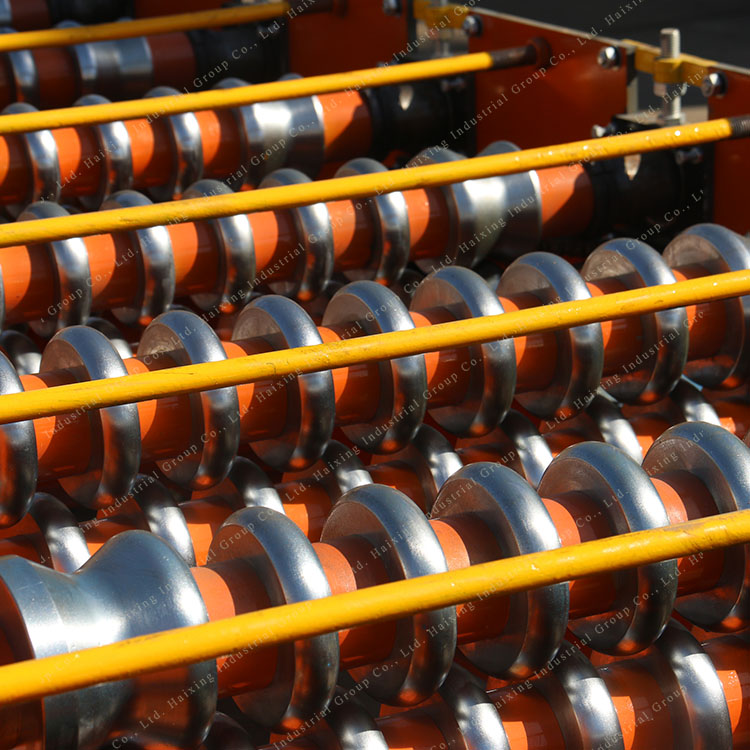

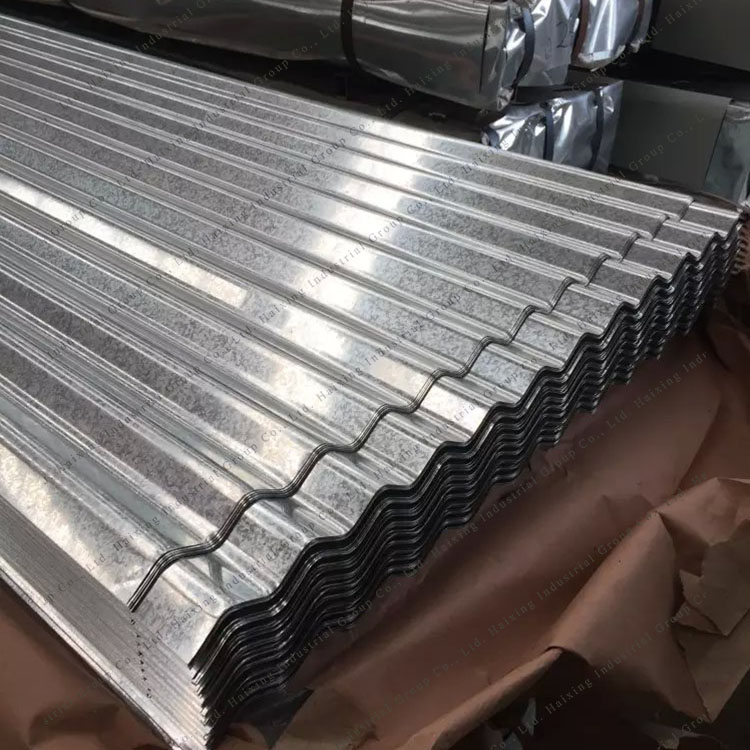

Coated Roof Tile Making Machine Product Description

Details of Coated Roof Tile Making Machine

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by the buyer in seller’s factory while before delivery.

Delivery: 30 days after receipt of advance payment