We consistently carry out our spirit of ”Innovation bringing enhancement, Highly-quality making sure subsistence, Management promoting profit, Credit score attracting prospects for Supply OEM Manufacture Metal Roofing Galvanized Corrugated Steel Sheet Tile Making Machine Color Steel Roll Forming Machine, Our experienced technical workforce will probably be wholeheartedly at your support. We sincerely welcome you to go to our internet site and business and deliver us your inquiry.

We consistently carry out our spirit of ”Innovation bringing enhancement, Highly-quality making sure subsistence, Management promoting profit, Credit score attracting prospects for Metal Roof Roll Forming Machine, Metal Roofing Roll Forming Machine, Steel Sheet Roll Forming Machine, If you are interested in any of our solutions or would like to discuss a custom order, you should feel free to contact us. We have been looking forward to forming successful business relationships with new clients around the world in the near future.

Metal Roof Sheet Tile Making Machine Glazed Tile Forming parameters

| 1 | Main motor power | 4kW, 3 phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Main frame | 300/350 mm H-beam |

| 7 | Backboard thickness | 16 mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Productivity | 0-15/ min |

| 12 | Roll station | 13 roll steps (according to different design) |

| 13 | Roller diameter | 70 mm (depends on different design) |

| 14 | Roller material | 45# steel |

| 15 | Cutter material | Cr12 |

| 16 | Cr-plating size | 0.05 mm |

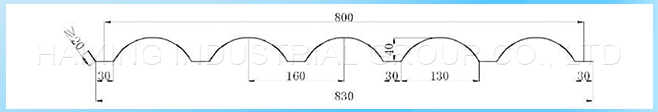

Tile drawing of Metal Roof Sheet Tile Making Machine Glazed Tile Forming

Machine details

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.

Packaging details of Metal Roof Sheet Tile Making Machine Glazed Tile Forming:

1. The main roll forming machine package by Plastic film;

2. Tighten to the container with steel wire rope and welded machine with the container by angle iron;

3. PLC control system and motor pump are packed in a box with waterproof paper coverage;

4. We have a professional loading technician to ensure that the goods are loaded into the container without any damage.

FAQ:

Q:How is this machine’s service life?

A:In the normal maintenance, the service life at least 8 years.

Q:Can you be responsible for transport?

A:Yes, please tell me the destination port or address. We have rich experience in transport.

Q:can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.