By using a sound small business credit, excellent after-sales provider and modern producing facilities, now we have earned an exceptional track record between our clients across the whole world for Supply OEM 300,600,1200,1800,2400mm Length Acrylic Sheet Bending Machine, With the advancement of society and economy, our enterprise will continue to keep a tenet of “Focus on trust, high quality the first”, moreover, we expect to produce a wonderful future with each customer.

By using a sound small business credit, excellent after-sales provider and modern producing facilities, now we have earned an exceptional track record between our clients across the whole world for 1200mm Acrylic Plastic Bending Heater, 1800mm Acrylic Bending Heater, Acrylic Sheet Bending Machine, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

|

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

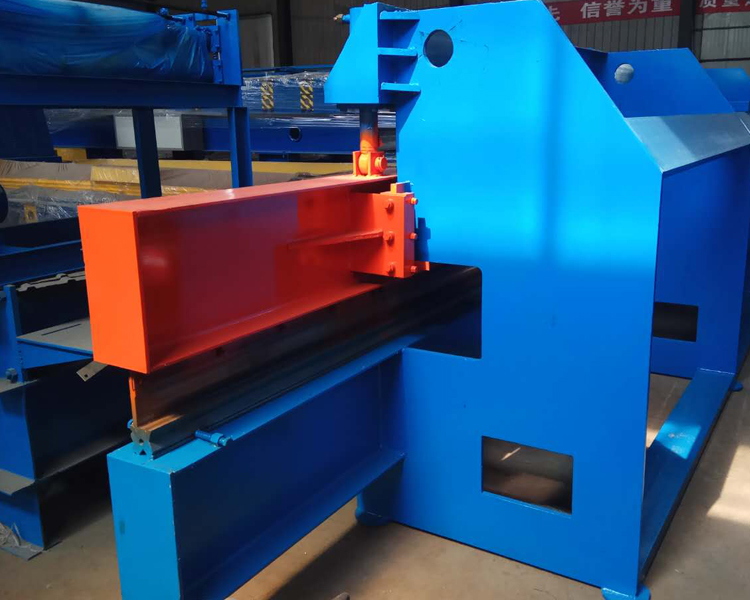

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Supply OEM/ODM Design Light Steel Keel Forming ...

-

Best Price Light Steel Keel Furring Channel Mac...

-

Hot New Products China Light Gauge Steel Framin...

-

Newly Arrival -end Low Roof Panel Ridge Cap Til...

-

OEM China China Light Steel Keel Profile Frame ...

-

2019 New Style Trapezoid panel forming machine ...