We constantly continually give you essentially the most conscientious client provider, plus the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Supply ODM Roof Metal Panel Forming Machine,Ridge Tile Panel Sheet Rollforming Machine,Metal Roof Ridge Cap Roll Forming Machine, We’ve been honest and open up. We glance ahead on your pay a visit to and developing trustworthy and long-term standing relationship.

We constantly continually give you essentially the most conscientious client provider, plus the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Automatic Used Roofing Metal Roof Panel Roll Forming Machine s Rolling Machine, Making Curved Metal Roofing Panel Forming Machine, Roof Metal Panel Forming Machine, Our company sticks to the principle of “high quality, reasonable price and timely delivery”. We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

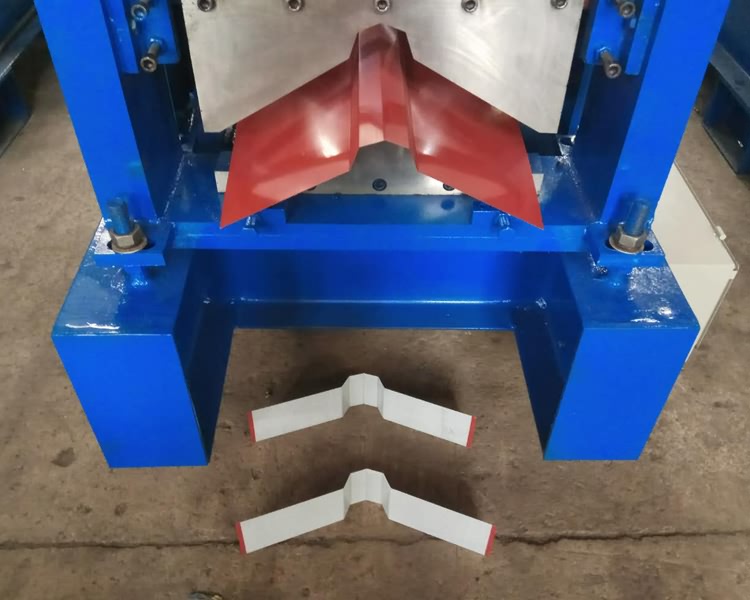

We can manufacture and design various color steel ridge cap roll forming machines according to customer requirements.

|

Color Steel Ridge Cap roll Forming Machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

Machine details:

Contact details

If you have any needs or questions, please feel free to contact us. We will be waiting for you here 24 hours. Please join us.

-

Cheapest Factory China Steel Coil Metal Sheet L...

-

Price Sheet for Electromagnetic Manual Sheet Me...

-

OEM Manufacturer Rolling Shutter Door Frame Mac...

-

2018 High quality Slitting Line Decoilslittingr...

-

Supply OEM Hot sale high quality high frequency...

-

Super Purchasing for Roller Shutter Door Machine