| Material Width | 914-1580mm |

| Effective Width | 680-1350mm |

| Thickness of Raw Materials | 0.80—1.5mm |

| Application | Wall Sheet and Roof Sheet |

| Machine Dimension | 12500mmX1600mmX1650mm |

| Total Weight | 10.2 Tons |

| Main Power | 15KW*2 |

| Decoiler | Manual or Hydraulic Decoiler |

| Inner Diameter | 508–610mm |

| Forming Speed | 10-15m/min |

| Forming Station | 24 Rows |

| Diameter of the roller | 90mm |

| Roller materials | 45# forging steel |

| Hydraulic pressure | 18-20Mpa |

| Chain size | 2 Inch |

| Material of Shaft | High Grade 45# Steel with 1st Rough Finished and

then 2th Refined Finished |

| Material of Roller | High Quality 45# forging steel with chromium plate 0.05mm ,the spacers with 15mm seamless pipe precision doing |

| Processing Technology | Rough Processing —Refined Processing–Hard Chromium Plating |

| Control system | PLC(Delta)-you can choose Mitsubishi, panasonic, Siemens |

| Voltage | 380V, 3-Phases, 50Hz |

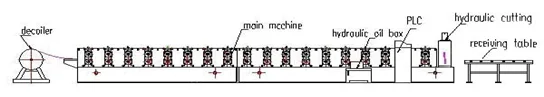

2.Components of line

Decoiler——————————————————————————– 1set ;

Main machine for roll forming——————————————————– —1set ;

Control system————————————————————————–1set ;

Hydraulic system————————————————————————1set ;

Automatic cutting————————————————————————1set ;

Output table—————————————————————————–1set ;

3.Work flow

Hydraulic Decoiler with Coil Loading Car → Guided Feeding →Roll Forming→

Hydraulic Tracking Cutting → 12 m Automatic Stacker

Products Showing

1.Steel tile decking floor sheet roll forming machine popular profile

2.Steel tile decking floor sheet roll forming machine showing

Packaging & Shipping

1. 40 feet container 2.PVC film package 3. according to customer requirement