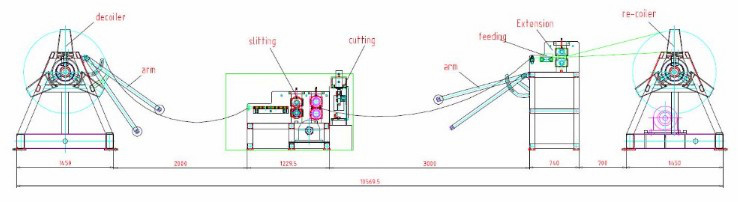

Leveling and Slitting Production Line working flow

The steel coil sheet uncoiling leveling slitting recoiling machine line includes in decoiler, guiding device, slitting device, cutting device, length measure device, extension device, re-coiler, hydraulic station and PLC controlling system.

Each parts of main details of Steel Coil Slitting Line Machine:

A. Hydraulic decoiler

Single cantilever structure bearing capacity 12 Tons.

Support range: 470-530mm.

Mandrel Expansion: hydraulic tension.

Electric unwinding power: 7.5KW frequency conversion.

Hydraulic pump: 4Kw.

B. Shovel head leveling device

Hydraulic shovel head with two shafts.

Total 11rollers (Up: 5 rows, down: 6 rows).

Roller diameter: 110mm.

After the steel coil on the decoiler enters the working position, Cylinder action of the pressure roller device, Roller falling, pressed on a steel strip coil, starter motor, rotating the steel strip on the reel. Shovel head out, steel plate enters the feed roller along the shovel head, passing the pinch of the feed roller and then passing it forward.

C. Slitting part

Slitting rollers

Diameter: 160mm-180mm.

Materials: 40Cr.

Blade tool

Outer diameter: 260-300mm.

Thickness: 10mm.

Number: 5Blades*6pieces

Materials: Cr12MoV.

Matching ruler steel sleeve, can adjust the size. The rubber sleeve is removed to prevent the strip and the board from being damaged.

Hydraulic control change the blades memorial arch.

Main motor power: 15KW speed regulation.

D. Hydraulic cutting machine

Double cylinder diameter: 70mm.

Guide column structure.

E. Waste materials collection

LiJu Motor.

Power: 2.7KW.

2sets.

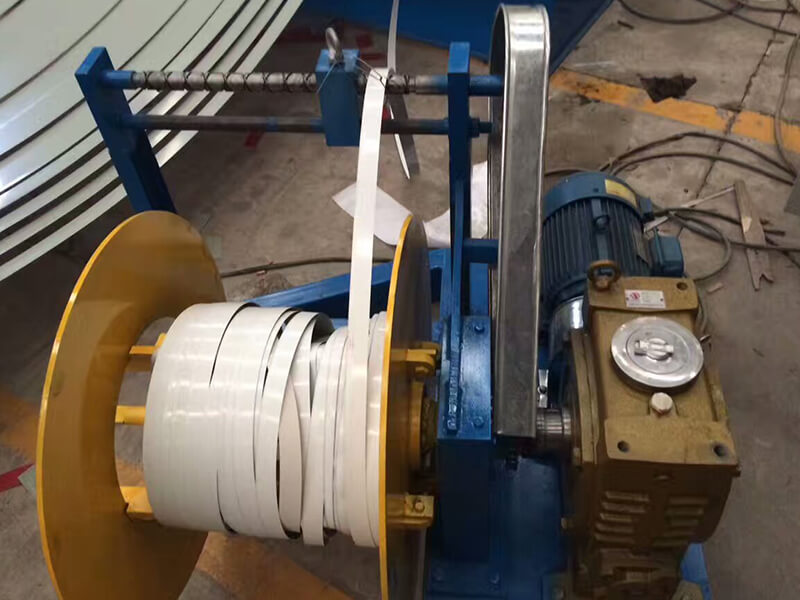

F. Hydraulic re-decoiler with coil car

With quick adjustment separator tray.

inner diameter: 500-530m.

Max outer diameter: 1600mm.

Load bearing: 12T.

Single cantilever structure hydraulic tension adjustment.Include hydraulic unloading trolley and press arm, power 7.5KW speed regulation.

G.Two sets of hydraulic system and two sets of control system.

Voltage: 380V 50HZ 3Phase or based on customer’s local need.