Automatic CZ interchange purlin machine process flow:

Manual decoiler– punching hole– roll forming machine– molding press– PLC control box– hydraulic system– post cut– output table.

The machine comprises the following parts:

Single-end feeding machine(max capacity 5T), Feeding leveling, Forming system, Straightening mechanism(one word original), At single + double holes, After forming shear system, Supporting material platform(6m)

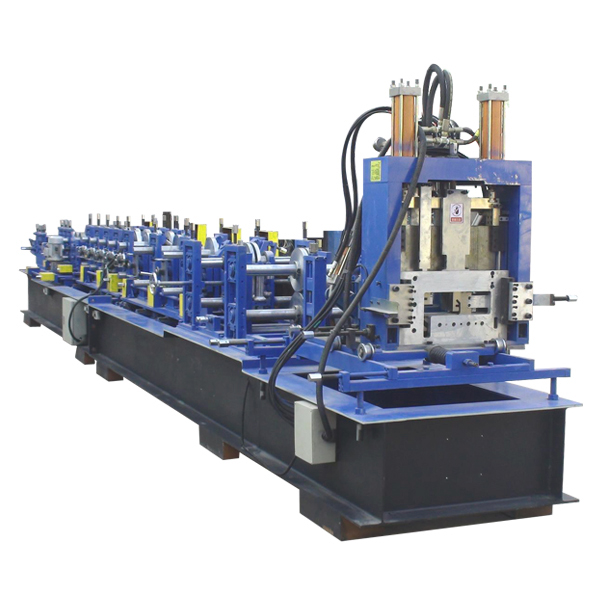

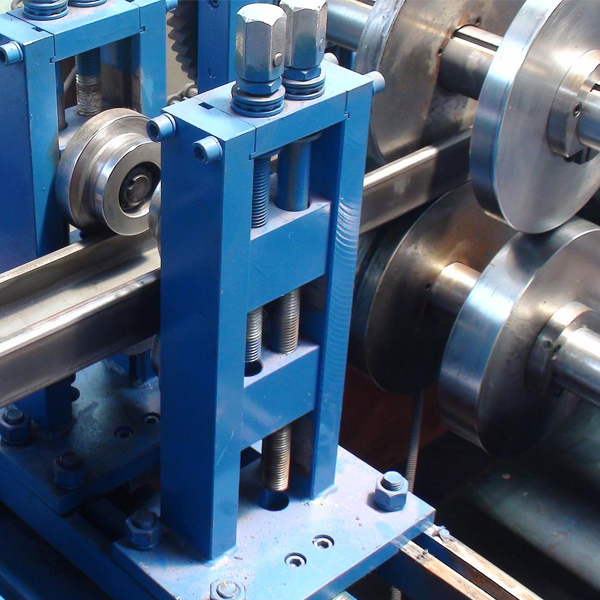

Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit

2. Package: export standard package for container

3. Payment: TT(30% by TT in advance, 70% by TT after inspect the machine before delivery)

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.