We always do the job to be a tangible team to ensure that we can present you with the very best good quality as well as the best cost for Special Design for Metal Roofing Trapezoid Iron Sheet Roll Forming Making Machine Hf, Constantly for the majority of business enterprise users and traders to supply ideal top quality products and great service. Warmly welcome to join us, let’s innovation with each other, to flying dream.

We always do the job to be a tangible team to ensure that we can present you with the very best good quality as well as the best cost for Metal Roofing Sheet Machine, Roll Forming Making Machine, Trapezoid Iron Sheet Machine, All styles appear on our website are for customizing. We meet up to personalized requirements with all products and solutions of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

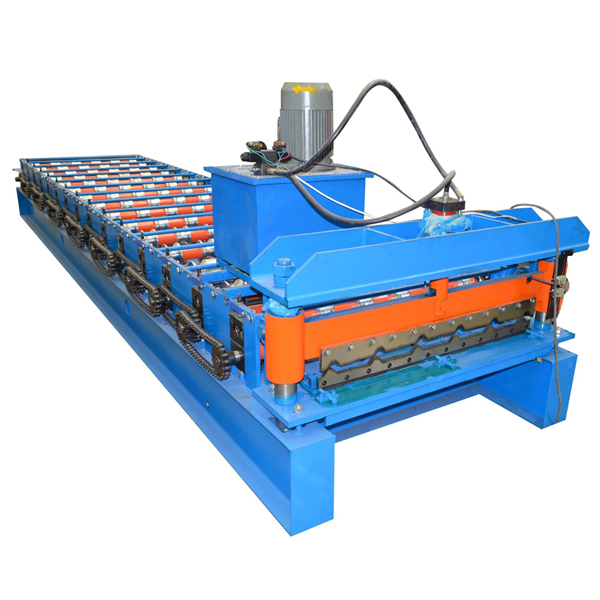

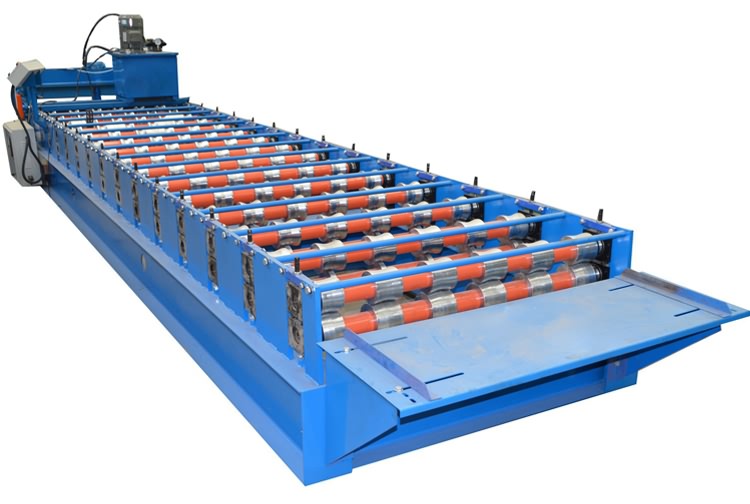

Aluminum trapezoidal roof making machine can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

|

Aluminum Trapezoidal Roof Making Machine Parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Detail of machine:

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

New Delivery for Standing Seam Arc Metal Roof P...

-

Factory Supply Best Sandwich Panel Portable Rol...

-

Factory Customized Automatic Level Machine/ppgi...

-

Hot Sale for Color Steel Sheet Roller Shutter D...

-

Quoted price for Hot Coil Stretch Precision Lev...

-

Low price for Roller shutter roll forming machi...