So that you can supply you with comfort and enlarge our company, we also have inspectors in QC Workforce and guarantee you our greatest service and item for Special Design for Coated Aluminum Coil Corrugated Used Metal Roof Roll Forming Sheet Bender Panel Machines, We also be sure that your selection might be crafted with the optimum quality and dependability. Please sense cost-free to make contact with us for further details.

So that you can supply you with comfort and enlarge our company, we also have inspectors in QC Workforce and guarantee you our greatest service and item for Coated Aluminum Coil Corrugated Used Metal Roof Panel Machine, Metal Roof Roll Forming Machines, Sheet Bender Machine, Our objective is “to supply first step products and solutions and best service for our customers, thus we have been sure you ought to have a margin benefit through cooperating with us”. If you are interested in any of our goods or would like to discuss a custom order, make sure you feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.

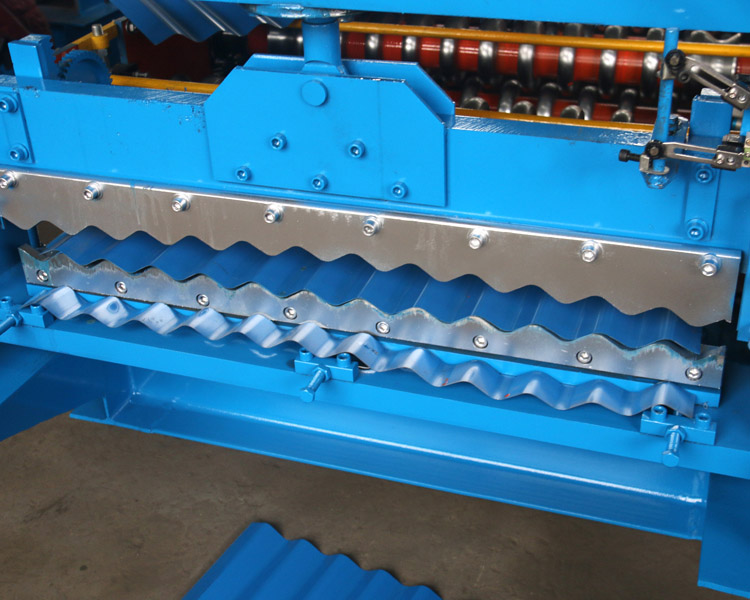

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.