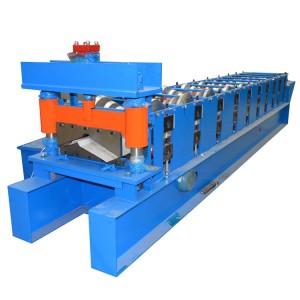

Snap lock metal tile making machine parameters

| 1 | Suitable to process | Color alu-zinc steel coil/Aluminium Coil |

| 2 | Roller | 16Rows |

| 3 | Dimensions | 7.0*1.3*1.55m |

| 4 | Motor Power | 7.5Kw |

| 5 | Pump Station Motor | 5.5Kw, Lichao Brand |

| 6 | Thickness of the plate | 0.6-1.2mm |

| 7 | Productivity | 10-15m/min |

| 8 | Material of the cutting blade | Cr12,Quenched treatment 58℃-60℃ |

| 9 | Diameter of the roller | Φ90mm |

| 10 | Weight | About 4800kgs |

| 11 | Main structure of the machine | 400H beams |

| 12 | Processing precision | Within 1.0mm |

| 13 | Side panel of machine | 20mm |

| 14 | Chain Wheel and Cycle Chain | 1 Inch |

| 15 | Voltage | 380V 50Hz 3phases or as customer’s need |

| 16 | Control system | PLC control (Delta) |

| 17 | Frequency system | Delta |

| 18 | Drive mode | Motor driver |

| 19 | Touch screen | Delta |

| 20 | Rolling materials | 45# forging steel with chromium plate |

| 21 | Length Tolerance | ±2mm |

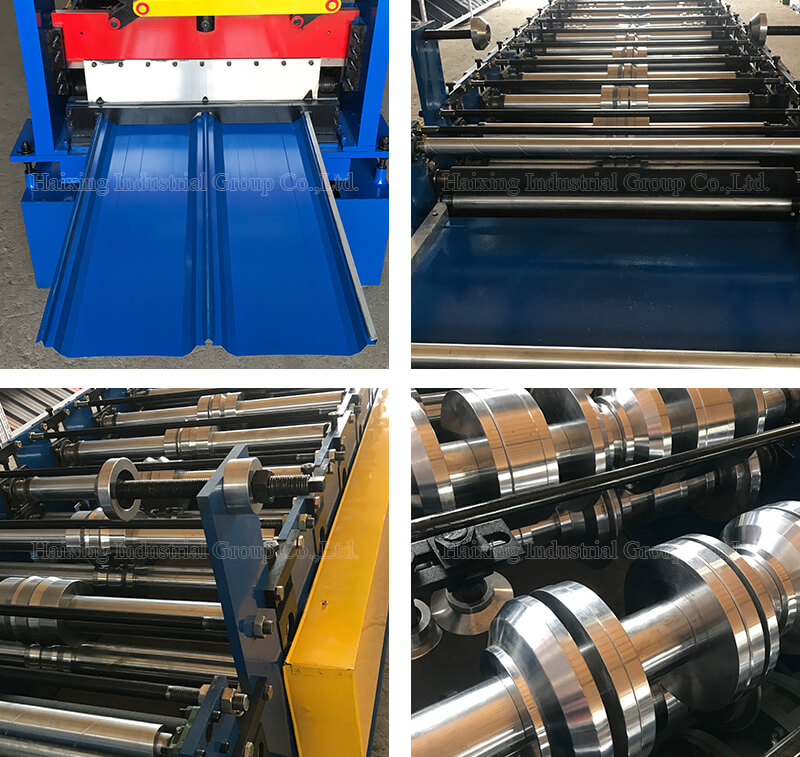

Picture details of Snap lock metal tile making machine

Roof roll forming machines has different types which used together with corrugated sheet and IBR sheet, or glazed tile sheet, selflock roof machine. The metal sheet is widely used in many kinds of industrial factory, civilian buildings, and Roof board for attached part product It has advantage of pretty appearance, durable using and so on.

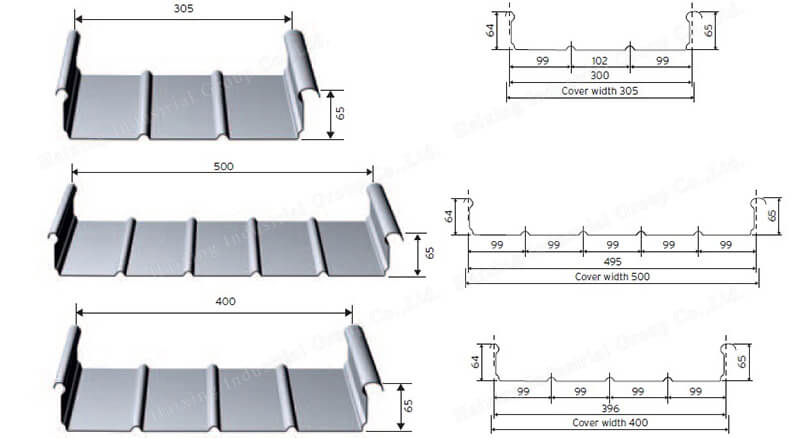

For the snap lock metal tile making machine, we commonly use the profile as following:

Snap lock metal tile making machine packaging Details

a.The main body of machine with water-proof plastic, then fixed to container by 8mm diameter steel wire and angle iron.

b.Rollers and shafts are covered with anti-rust oil.

c.PLC control system and motor pump are packed with waterproof paper and plastic film.

d.Spare parts in a carton box.

e.Manual decoiler was nude packing.

f.The output-table put into a carton box.

g.If the machine is too long, we will divide it into two parts and pack them in one package with steel wire.

h.Fit for ocean shipping.