Shutter door forming machine with hydraulic guide column cutting parameters

| 1 | Uncoiler | 3 tons manual uncoiler |

| 2 | Feeding guide | 2 roller feeding guide |

| 3 | Forming rollers | 14 station rollers |

| 4 | Roller material | 50mm diameter cr12 steel, with twice CNC precise process |

| 5 | Forming body | 100mm x 80mm square pipe with 3.5mm |

| 6 | Forming body outside | With 16mm steel plate welded |

| 7 | Transmission | Gear transmission |

| 8 | Raw material | Galvanized steel, galvalume steel, color steel coil |

| 9 | Raw material thick range | 0.5mm to 1.2mm |

| 10 | Unloading support | 2 pieces 3 meters |

| 11 | Main motor | 3KW/4KW |

| 12 | Pump motor | 3KW/4KW |

| 13 | PLC control system | Automatic control system, language: English, Spanish, Russian and so on. |

| 14 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan. Other elements are from famous suppliers of China. |

| 15 | Cutter blades | Cr12 mold steel with quenched treatment. |

| 16 | Factory area | The machine is the 7m length and 2m width, and output sheet according to the customer the longest sheet to calculate |

| 17 | Warrant time | 14 months |

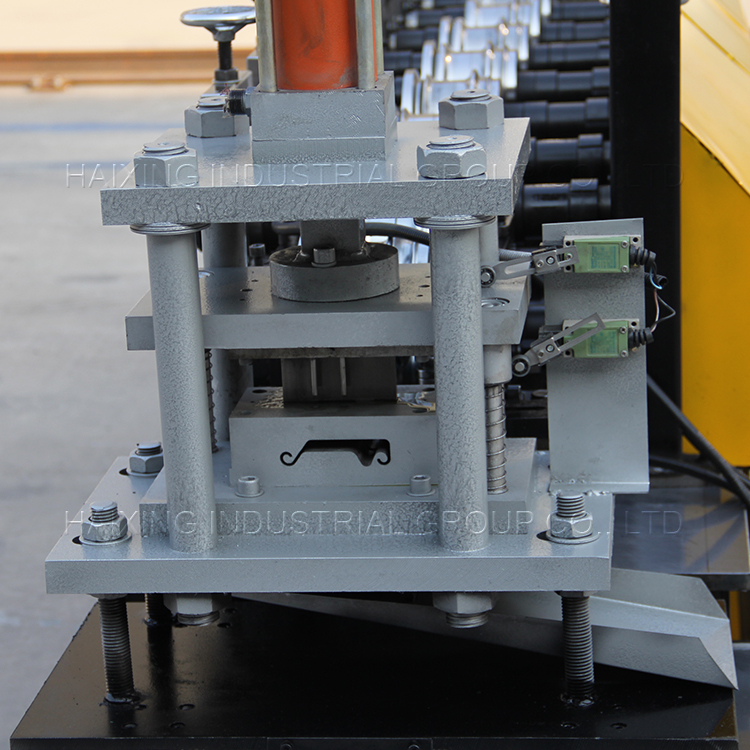

Machine pictures:

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.

Material:

1) Coil width: 136 mm or 125 mm;

2) Suitable coil thickness: 0.6-1.0 mm;

3) Suitable raw materials: galvanized (GI), we test machine as our 114 mm width steel coil;

4) The yield strength of raw material: 235 Mpa-550 Mpa.

Machine components:

1) Manual decoiler*1 pcs (capacity: 3 tons);

2) Guiding equipment*1 pcs;

3) Roll forming equipment*1 pcs;

4) Post cutting blade*1 pcs;

5) Hydraulic station*1 pcs;

6) PLC control system*1 pcs;

7) Receiving table*1 pcs.