We insist on offering high quality production with good business concept, honest sales and the best and fast service. it will bring you not only the high quality product and huge profit, but the most significant is to occupy the endless market for Short Lead Time for Automatic Punching Twist C/z Purlin Rool Forming Machine, Safety by means of innovation is our promise to each other.

We insist on offering high quality production with good business concept, honest sales and the best and fast service. it will bring you not only the high quality product and huge profit, but the most significant is to occupy the endless market for Channel Forming Machine, Cold Roll Steel Roll Forming Machine, Roll Forming Machine, Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our products, please feel free to contact us. We would love to provide you with further information.

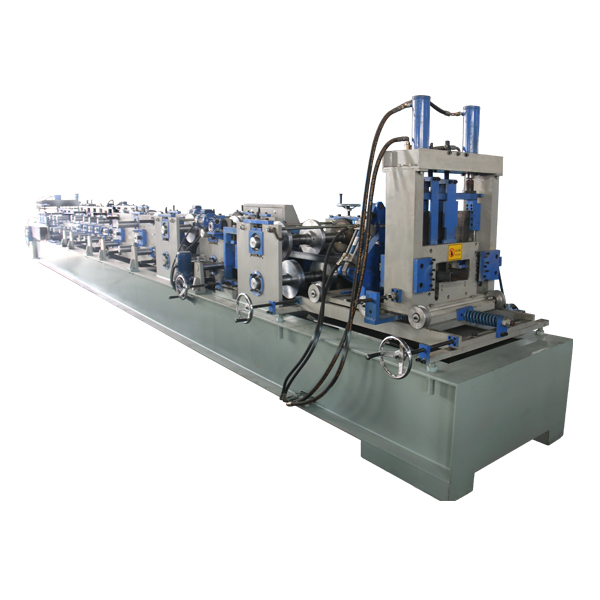

Automatic CZ interchange purlin machine process flow:

Manual decoiler– punching hole– roll forming machine– molding press– PLC control box– hydraulic system– post cut– output table.

|

Purlin roll forming machine |

||

| 1 | Suitable to process | Steel plate |

| 2 | Rollers | 18 rows(Before and after the leveling and contains no lead to send passes) |

| 3 | Dimensions | 11*1.3*1.5m |

| 4 | Power | 11.5kw+7.5kw |

| 5 | Thickness of the plate | 1-3mm |

| 6 | Productivity | 8-10m/min |

| 7 | Middle plate thickness | 20mm |

| 8 | Driving ways | 2.6-inch China wheels and link chain |

| 9 | Diameter and material of the forming axis | 80mm |

| 10 | Weight | About 8.5T |

| 11 | Voltage | 380V 50HZ3 phase |

| 12 | Roll material | GCr15(bearing steel)hard chrome plated after heat treatment |

| 13 | Shaft material | 40Cr Modulation of heat treatment after polishing hard chromium plating |

| 14 | On both sides of the wall material | A3 steel |

| 15 | Frame | International H-beam |

| 16 | Blade material | Cr12Mov |

| 17 | Forming wheel | Bearing steel quenching |

The machine comprises the following parts:

Single-end feeding machine(max capacity 5T), Feeding leveling, Forming system, Straightening mechanism(one word original), At single + double holes, After forming shear system, Supporting material platform(6m)

Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit

2. Package: export standard package for container

3. Payment: TT(30% by TT in advance, 70% by TT after inspect the machine before delivery)

-

Cheap price Metal C Shape Furred Ceil Studs Tra...

-

Cheap PriceList for Steel Door Making Machines,...

-

Factory Price China 312 High Quality Ridge Cap ...

-

PriceList for Light Steel Keel Roll Forming Mac...

-

Factory For Galvanized Steel Door Frame Roll Fo...

-

Manufactur standard Wpc Wall Panel Production L...