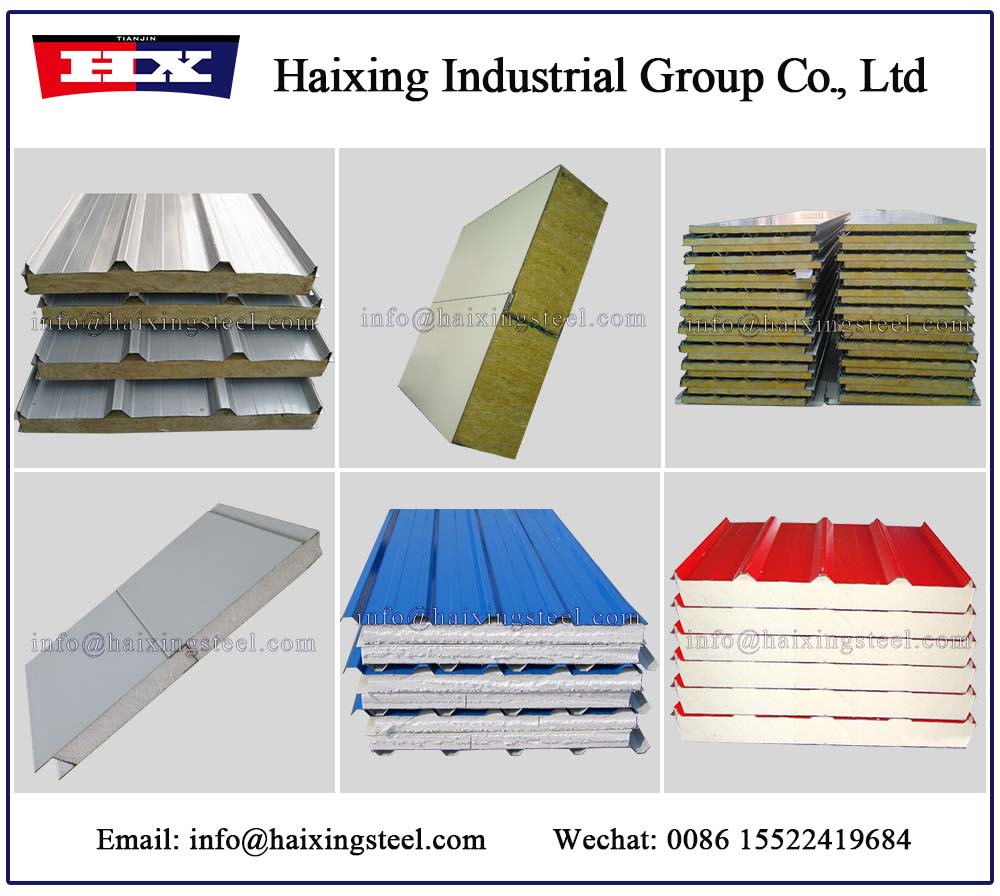

Rockwool Sandwich panel as kind of construction material is widely used in construction, heat preservation, packaging, frozen, daily necessities, industrial casting, etc.

It can also be used to display the assembly places, commodity cabinet, signs and toys manufacture.

It mainly applies to the wall exterior insulation, heat preservation, floor heating in the wall to adapt national building energy requirements.

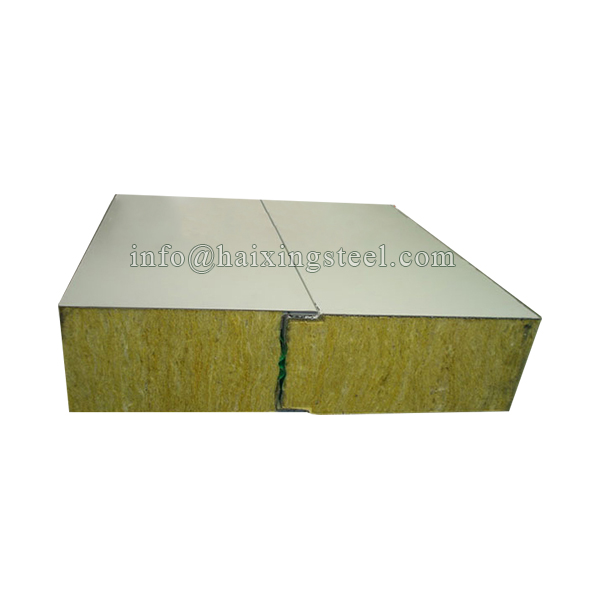

Main parameters

| Thickness |

60/75/90/100/120/150/180mm |

| Material of the panels |

composed of colorful steel sheets and EPS |

| Unit Weight of Core Material |

8-16 kg/cbm |

| Width of the panels |

950mm for wall and 960mm for roof |

| Panels type |

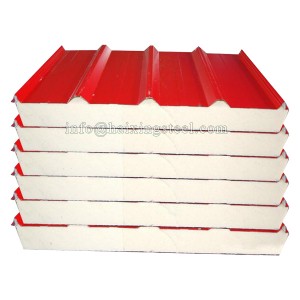

Wall panel and Roof panel |

| Surface Texture and Appearance |

Small wave, Flat, Embossment, Big rib |

| Heat Insulating Material |

EPS (Polystyrene) |

| Thickness of steel sheet |

PPGI/PPGL:0.3-0.8mm (PE or PVDF Coating) |

| GI/GL:0.3-0.8mm (Zinc coating 40-275g/m2) |

| Stainless steel:0.4-0.8mm |

| Aluminum sheet :0.5-1.0mm |

| Color of the coating |

Ocean Blue ,Grey White or Customized |

| Type of sheet Coating |

PVDF, HDP, SMP, PE |

| Type of Base steel sheet |

Hot-dip galvanized, Al-Zn coated |

| Insulation density |

Rock wool:80–120kg/m3 Glass wool:48kg/m3 |

| Characteristic |

Good temp-keeping and heat insulation |

| Installation |

Convenient and flexible without the large- size lifting devices so that the construction period is limited with the lower comprehensive costs |

| Fine fireproof |

Test by national quality inspection center for fireproof building material, all its index reach grade A1 |

| Heavy load bearing capacity |

High strength and high rigidness and is suitable either for the weight – bearing structure or for the protective structure |

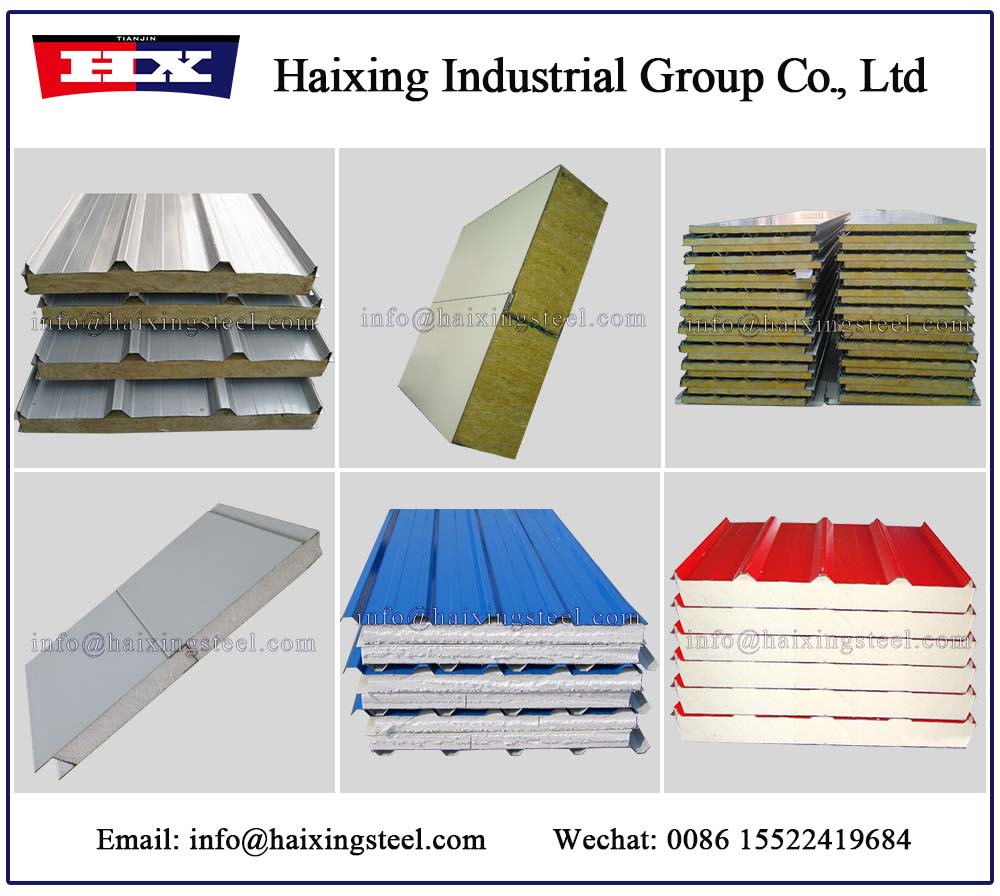

Sandwich pannel photos

Advantages

1. Increased supporting strength

2. Reduced project cost

3. Light weight

4. Easy and fast for installation

5. Durable: 20 years

6. Fire, Water Proof

Company profile

Our company adheres to the service tenet: quality first, reputation first. We believe that quality is the lifeblood of the company. We will provide satisfactory products and after-sales service for every customer.

We have a variety of machinery and production methods to meet the growing needs of our customers.

Our different types of roll forming are easy to operate and highly efficient for Canada, Korea, Pussia, Netherlands, Suriname, Sri Lanka, Malaysia, Vietnam, Nigeria, Tanzania, India, Mongolia, Armenia, Kazakhstan, Vladivostok, Bolivia, Azerbaijan, etc.

Previous: PU Sandwich Panel Roofing Tiles

Next: Automatic Sheet Coil Slitting Machine