Renewable Design for Metal Roofing C Stud Making Machines - Lowest Price for Full Automatic Fiber Cement Siding Board Production Line/corrugated Roof Tile Making Machine – Haixing Industrial Detail:

We’ve got state-of-the-art tools. Our goods are exported towards the USA, the UK and so on, enjoying a superb standing among consumers for Lowest Price for Full Automatic Fiber Cement Siding Board Production Line/corrugated Roof Tile Making Machine, We welcome you to definitely inquire us by simply call or mail and hope to build a successful and cooperative romance.

We’ve got state-of-the-art tools. Our goods are exported towards the USA, the UK and so on, enjoying a superb standing among consumers for Cement Siding Board Production Line, Corrugated Roof Tile Making Machine, Fiber Cement Siding Board Production Line, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

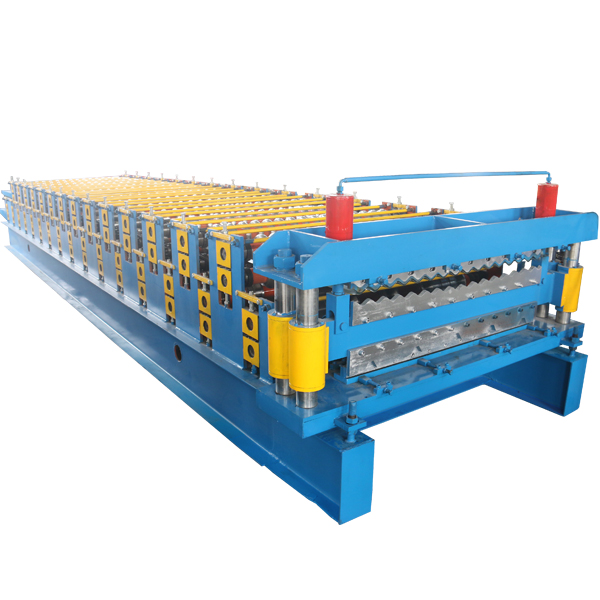

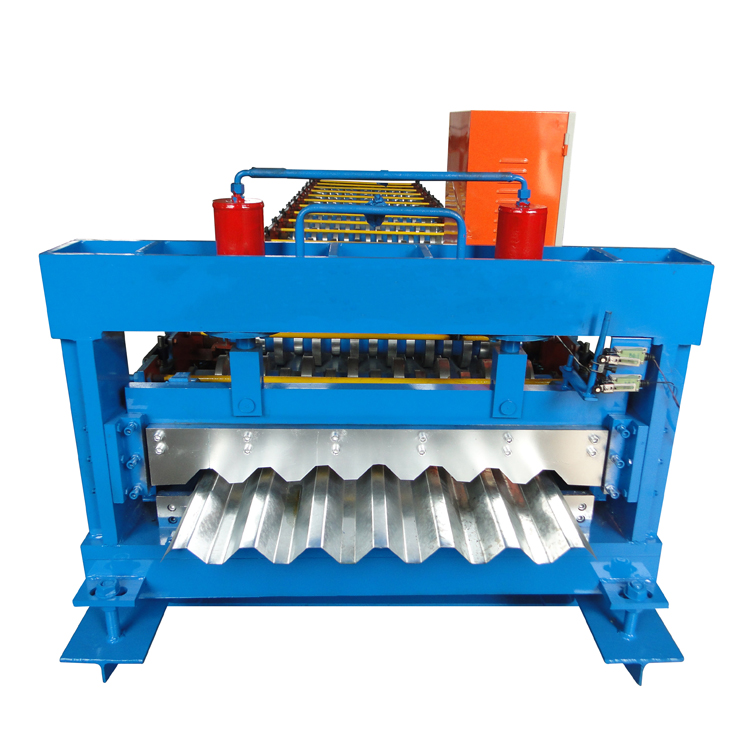

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

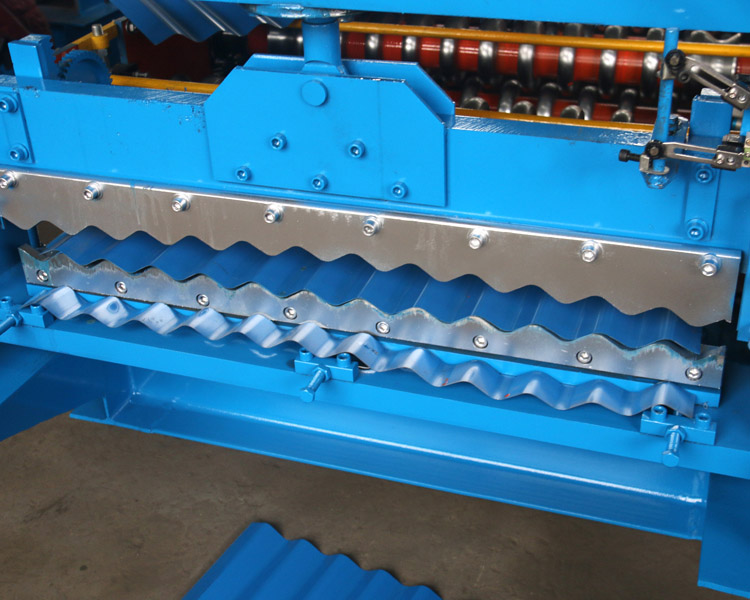

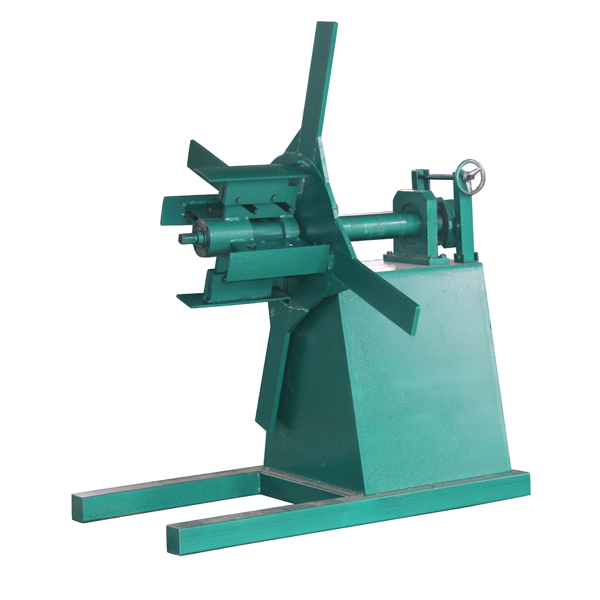

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Product detail pictures:

Related Product Guide:

Newbie designer Stuart Charles Towner on how he made it to Chelsea | Steel Downpipe Roll Forming Machine

This British mosque is structured with a flowering wooden lattice | Steel Downpipe Roll Forming Machine

Renewable Design for Metal Roofing C Stud Making Machines - Lowest Price for Full Automatic Fiber Cement Siding Board Production Line/corrugated Roof Tile Making Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Trending Products Industrial Fume Extractor - ...

-

OEM Factory for Stainless Steel Sheet Bending M...

-

OEM Supply T-Grid Cold Roll Forming Machine - ...

-

factory Outlets for Roof Truss Roll Forming Mac...

-

Factory wholesale Cnc Press Brake Machine - Ga...

-

2017 China New Design Hydraulic Pipe Punching M...