We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Reasonable price for Automatic Roof Panel Tile Press Roll Forming Machine, We welcome shoppers everywhere in the word to call us for long run small business associations. Our solutions are the top. Once Selected, Excellent Forever!

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Automatic Roof Tile Roll Forming Machine, Roll Forming Machine, Tile Press Machine, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

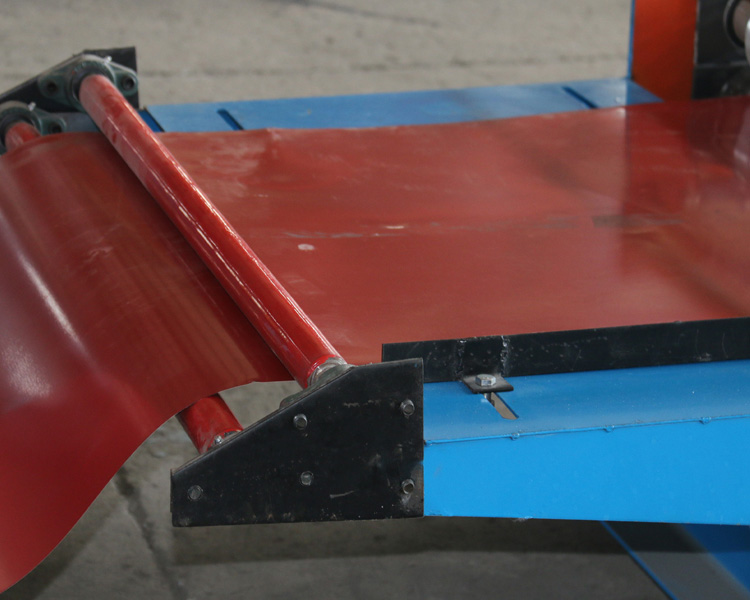

The tiles pressed out by the glazed roofing tile roll forming machine are very beautiful, and the technical parameters of the machine are as follows:

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 836mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Glazed roofing tile roll forming machine components include: Manual un-coiler, Guiding platform, Coil strip leveler, Main machine of roll forming, Electric-motor, Cutting device, Hydraulic station, PLC control and Supporter table.

Machine Details:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

High definition Stud And Track Light Steel Keel...

-

Good quality Automatic C Channel Steel Purling ...

-

Top Suppliers Asapvc 30 Years Warranty Roofing ...

-

High definition China 5t Hydraulic Decoiler Mac...

-

Good User Reputation for Standing Seam Metal Ro...

-

Wholesale Price China Indusry Metal Roof Rolled...