“Sincerity, Innovation, Rigorousness, and Efficiency” is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Reasonable price Automatic Roof Ridge Cap Forming Machine, We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

“Sincerity, Innovation, Rigorousness, and Efficiency” is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Automatic Roof Ridge Cap Forming Machine, Roof Ridge Cap Forming Machine, Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our items, you should feel free to contact us. We would love to supply you with further information.

Roof ridge cap roll forming machine parameters

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

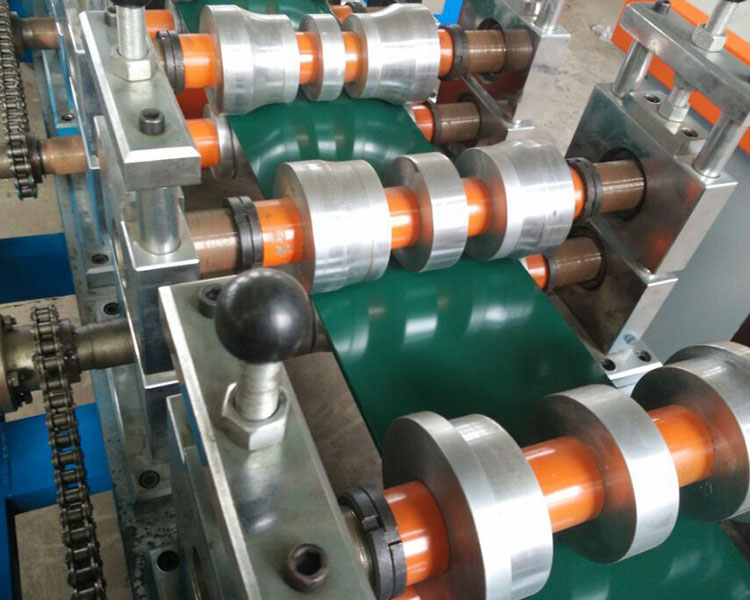

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

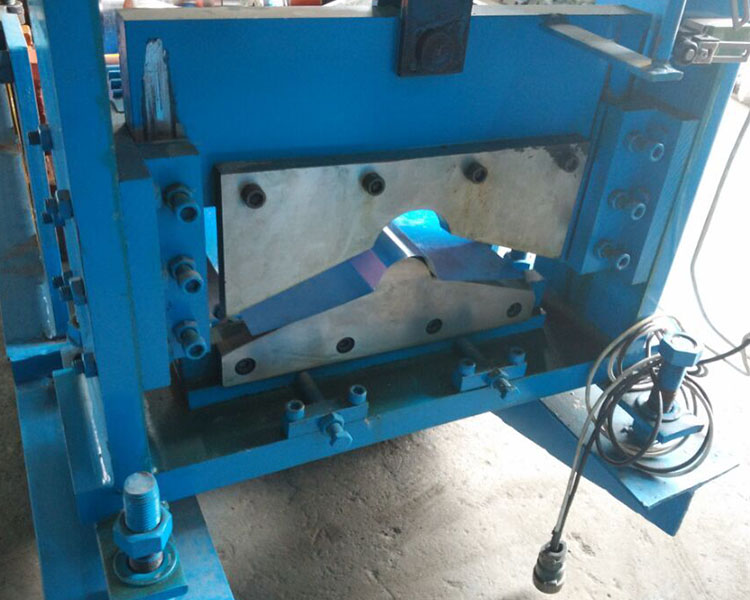

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

The color steel ridge tiles and aluminum-formed ridge tiles that are pressed out of roof ridge cap roll forming machine are lighter, easier to install and less expensive.

Machine details:

Package and shipment details:

The machines sold by Haixing Industrial Group Co., Ltd. use standard export packaging, as follows:

1*40GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.