Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for Quots for The Most Popular Galvanized Stainless Steel Glazing Roof Tile Making/roofing Roll Forming Machine, We are wanting ahead to setting up cooperative associations along with you. Please call us for more information and facts.

Our target should be to consolidate and enhance the high quality and service of existing goods, meanwhile frequently develop new products and solutions to fulfill distinct customers’ demands for Galvanized Steel Forming Machine, Roll Forming Machine, Steel Forming Machine, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our solutions have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

The tiles pressed out by the glazed roofing tile roll forming machine are very beautiful, and the technical parameters of the machine are as follows:

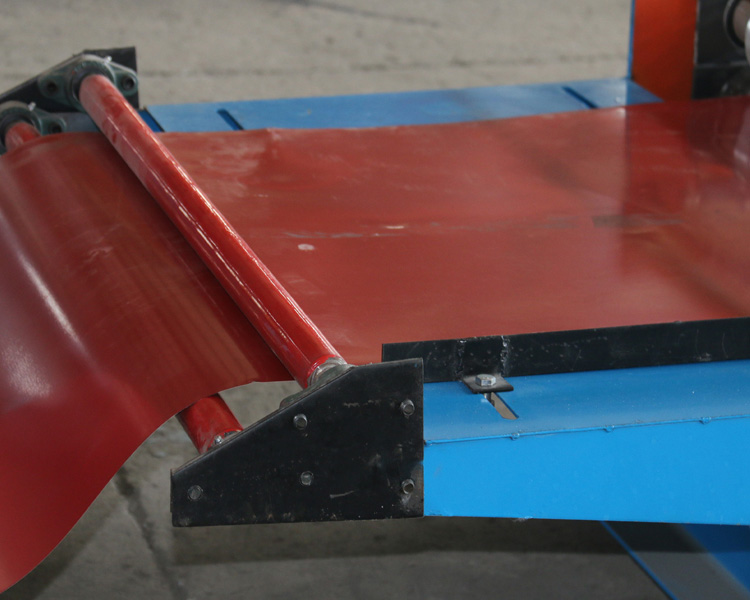

Glazed roofing tile roll forming machine components include: Manual un-coiler, Guiding platform, Coil strip leveler, Main machine of roll forming, Electric-motor, Cutting device, Hydraulic station, PLC control and Supporter table.

Machine Details:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.