The organization keeps into the procedure concept “scientific administration, premium quality and effectiveness primacy, consumer supreme for Quots for Metal Galvanized Aluminum Corrugated Steel Sheet Making Machine Colored Steel Wall Glazed Roof Panel Tile Roll Forming Machine, In case you have any comments about our corporation or products, you should experience no cost to call us, your coming mail will be remarkably appreciated.

The organization keeps into the procedure concept “scientific administration, premium quality and effectiveness primacy, consumer supreme for Cold Roll Forming Machine Aluminum Roof Panels Roll Forming Machinery Aluminum Metal Roll Forming Machine, Roof Panel Roll Forming Machine Bending Metal Sheet Roll Forming Aluminum Corrugated Sheet Roll Forming Machine, Steel Plate Cold Roll Forming Machine Automatic Metal Stud Machine Aluminum Metal Roof Panel Roll Forming Machine, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

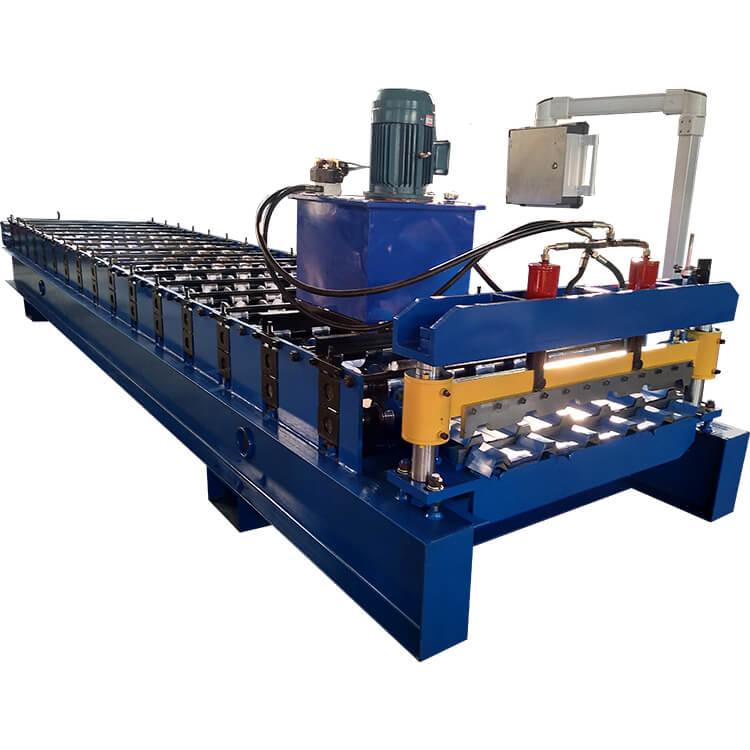

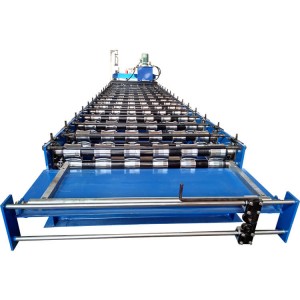

Roofing roll forming machine price parameters

| 1 | Main motor power | 5.5KW |

| 2 | Hydraulic motor power | 5.5KW |

| 3 | Hydraulic pressure | 10-12MPa according to the oil pump and pump motor |

| 4 | Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) |

| 5 | Control system | Automatic PLC control system |

| 6 | Mainframe | 350/400H beams according to machine demands |

| 7 | Wall sheet thickness | 16-22mm according to machine demands |

| 8 | Chain size | 1 /1.2inch according to machine demands |

| 9 | Feeding material | Galvanized steel coil, color steel coil, aluminum steel coil |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Productivity | 0 – 25m/min |

| 12 | Roll station | Common 11rolls or 25rolls |

| 13 | Roller diameter | 70mm, 75mm, 80mm (depends on different design) |

| 14 | Roller material | 45# steel |

| 15 | Cutter material | Cr12MOV |

| 16 | Cr-plating size | 0.05 mm |

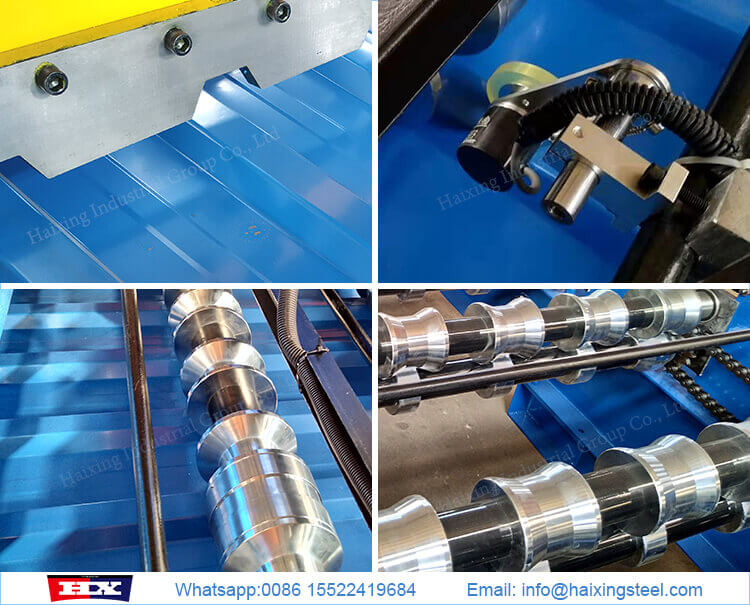

Roofing roll forming machine price picture details

Why choose us?

Our company has a professional team of engineers and export team.

- Engineer: 25 (2 engineers with more than 30 years of work experience, 5 engineers with more than 20 years of work experience, 8 engineers with more than 10 years of work experience, 10 engineers with more than 5 years of work experience);

- Factory workers: 88;

- Finance staff: 2;

- Purchasing staff: 12;

- Operator: 3;

- Sales staff: 8;

- After-sales staff: 5.

Warranty Policy

Our machine is warranted for 18 months. During the warranty period, if the damaged part cannot be repaired, we can send the new part for replacement of the damaged part for free, but you will need to pay the courier fee yourself.

If after the warranty period, we can negotiate to resolve the issue and provide technical support throughout the life of the device.

Drawing confirmation

——After confirming the final profile with the customer, the team of 12 engineers worked out detail workable parts CAD drawings;

——After 5 recheck, the production manager arrangement the material for all machine parts;

Start production

——Our company own 12sets rough lathe machine, 20sets precise lathe machine, and 30sets shearing machine, all machine parts start manufacture.

Product Inspection

——Our company Own 3sets hard test machine, and 4sets surface thickness Chromium test machine.

——Roller and shaft: Our Inspect team test 90% wheels and shafts, confirm all parts size precise and performance after processing.

——Our Inspect team test all roller surface, confirm all part surface paint above 5um.

——Main frame and medium plate: Our Inspect team test the main frame and plate cutting precise.

Assembling machine

——5 worker assemble and welding one machine body frame by three days.

Machine painting

——Putty ensure weld parts surface smoothly, and environment-friendly paint ensure protect worker body and environment.

Machine Manual use test

——Confirm the output sheet tolerance within 2mm.

Cutter production

——According the finally manufacture sheet, confirm the blade precise profile, Cr12MOV steel cutting knife finished by laser cutting.

Storage

——For protect machine surface clear and without damage, we paint again and package by film.

Packaging

Our products are usually available in two packaging methods: plastic film packaging and plastic film + wooden box packaging.

1. The main machine is covered with plastic film.

2. PLC control box, spare parts, and other small parts are packed by wooden cartons.

Delivery

Two days before delivery, we unpacked and repainted the machine and repackaged it.

1) Q: Do you have after-sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3) Q: How does your factory do regarding quality control?

A: Quality is the priority. we always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers’ specifications, using top brand name components.

5) Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.