Our purpose would be to give good quality items at competitive rates, and top-notch service to consumers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Quots for Customized Design Long Span Arched Steel Curving Corrugated Roof Machine, Sincere cooperation along with you, altogether will develop happy tomorrow!

Our purpose would be to give good quality items at competitive rates, and top-notch service to consumers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Arched Corrugated Roof Machine, Arched Steel Roof Machine, Long Span Steel Curving Roof Machine, Corporate goal: Customers’ satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

|

Galvanized Curving Roof Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

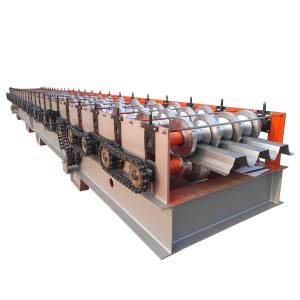

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

The advantages of galvanized curving roof machine:

1. Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2. Controlling by computer, PLC display, operation is easy, running is steady and reliable, endurable, maintenance-free.

3. We can make and designs will kinds of roll forming machine according to customer’s request.

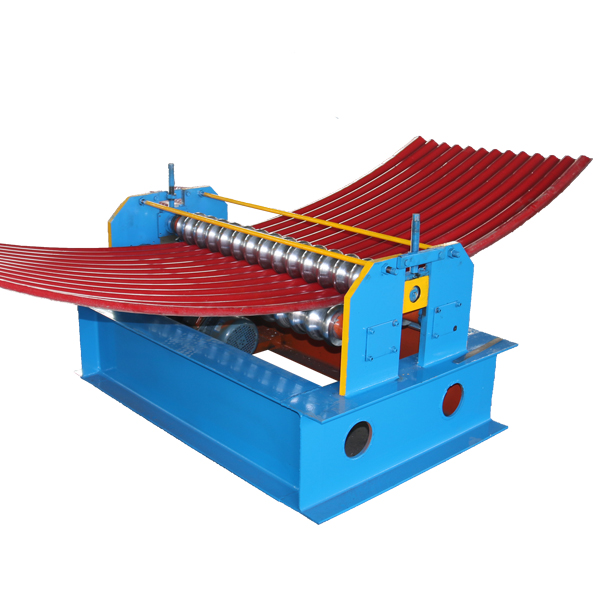

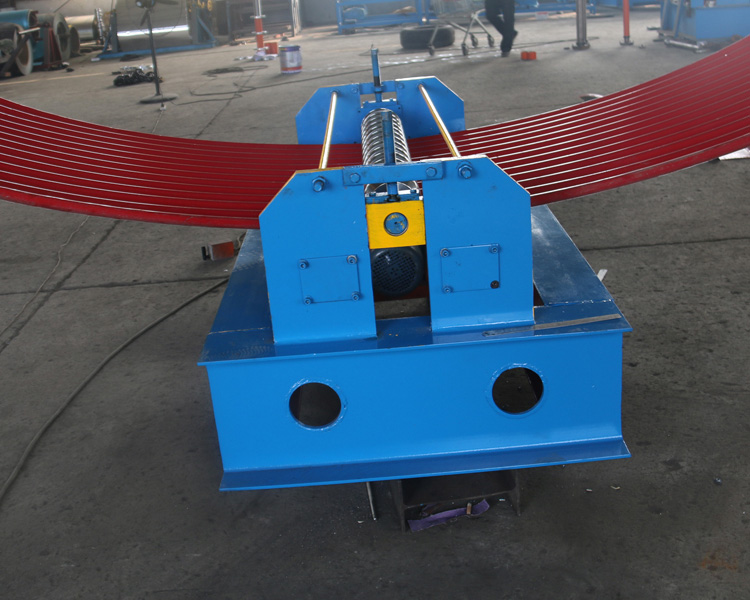

Machine photos:

-

OEM Customized China Slitting and Leveling Cutt...

-

Newly Arrival China Standing Seam Roof Former S...

-

Factory Supply C U Z Channel Purlin Cold Roll F...

-

Top Grade Metal roofing sheet crimping machine ...

-

Best-Selling Trade Assurance Steel Decking Floo...

-

CE Certificate Automatic Double-Deck Roof Tile ...