Quality Inspection for Solder Fume Extractor - Big discounting Trade Assurance Cast Iron Memorial Arch C Z U Profiles Keel Roll Forming Machine – Haixing Industrial Detail:

We insist over the principle of enhancement of ‘High high quality, Efficiency, Sincerity and Down-to-earth working approach’ to offer you with superb assistance of processing for Big discounting Trade Assurance Cast Iron Memorial Arch C Z U Profiles Keel Roll Forming Machine, We’ve expanded our business enterprise into Germany, Turkey, Canada, U. S. A. , Indonesia, India, Nigeria, Brazil and some other regions of your environment. We have been doing work hard being one with the ideal worldwide suppliers.

We insist over the principle of enhancement of ‘High high quality, Efficiency, Sincerity and Down-to-earth working approach’ to offer you with superb assistance of processing for C Z U Profile Forming Machine, U Profile Rolling Machine, U Profiles Keel Machine, Our company always concentrate on the development of the international market. We have now a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

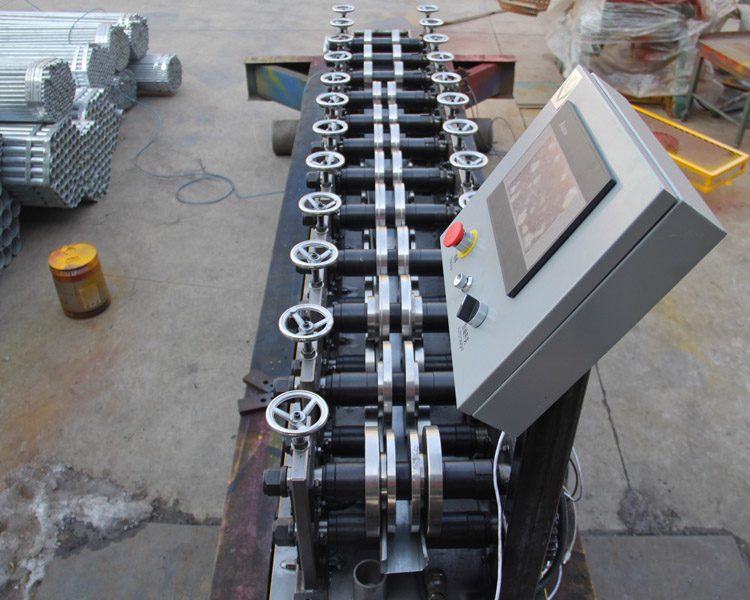

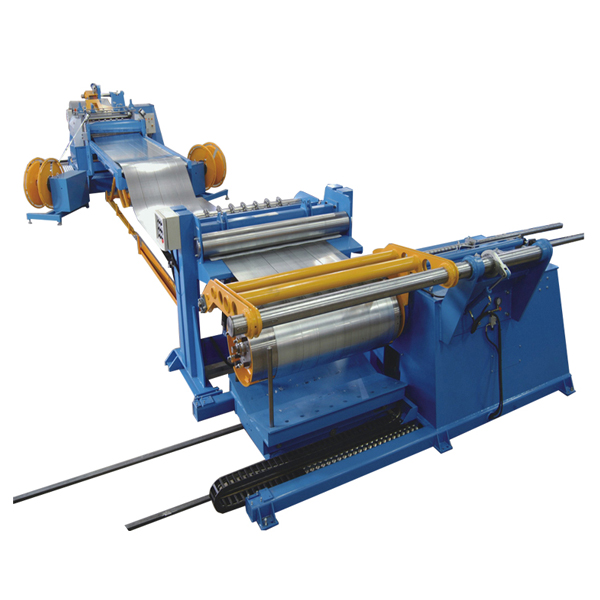

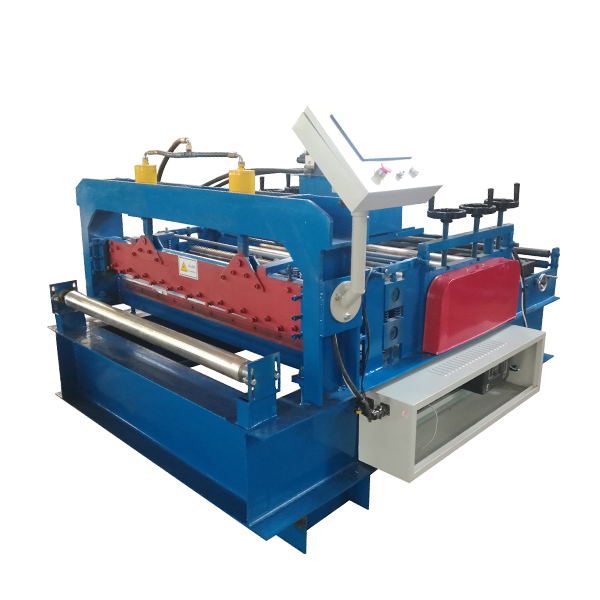

Equipment components of C channel light steel keel making machine:

Manual decoiling, roll forming machine, computer control system, hydraulic control system, cutting, run out table.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

C channel light steel keel roll forming machine picture display

Packaging Details:

1. Machine is covered by plastic film

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

In the Age of A.I., Is Seeing Still Believing? | Roof Sheet Curving Machine

Studio Morison’s shelter is designed for when nature reclaims the planet | Steel Downpipe Roll Forming Machine

Quality Inspection for Solder Fume Extractor - Big discounting Trade Assurance Cast Iron Memorial Arch C Z U Profiles Keel Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

PriceList for Automatic Die Blade Bending Machi...

-

Good User Reputation for Portable Fume Extracto...

-

China Factory for Customized C Purlin Roll Form...

-

Hot Selling for Zinc Roofing Sheet Roll Forming...

-

Best quality T Grid Ceiling Machine - Hydrauli...

-

Factory Supply Sheet Metal Roll Bending Machine...