Our goal is usually to consolidate and improve the high quality and service of existing solutions, meanwhile continuously create new items to meet unique customers’ requires for Quality Inspection for Colored Steel Roof Panel Making Roll Forming Machine, Customers’ profit and pleasure are constantly our biggest goal. You should contact us. Give us a probability, offer you a surprise.

Our goal is usually to consolidate and improve the high quality and service of existing solutions, meanwhile continuously create new items to meet unique customers’ requires for Color Steel Roof Panel Roll Forming Machine, Corrugated Wave Panel Making Roll Forming Machine, Roll Forming Machine, Our market share of our solutions has greatly increased yearly. If you are interested in any of our items or would like to discuss a custom order, you should feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future. We’re looking forward to your inquiry and order.

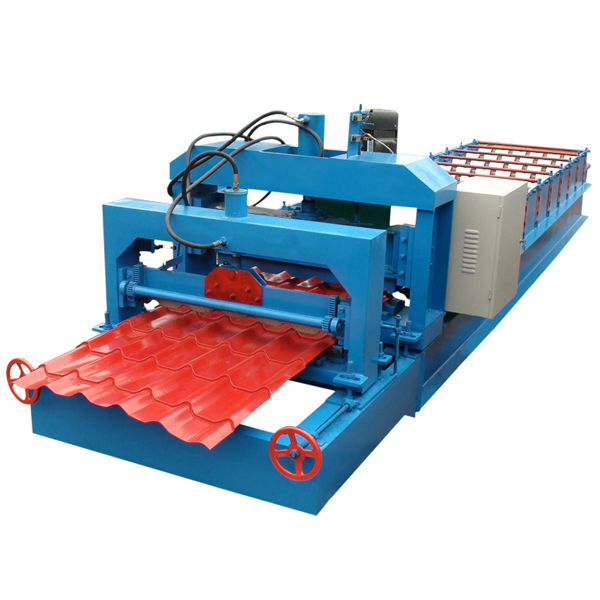

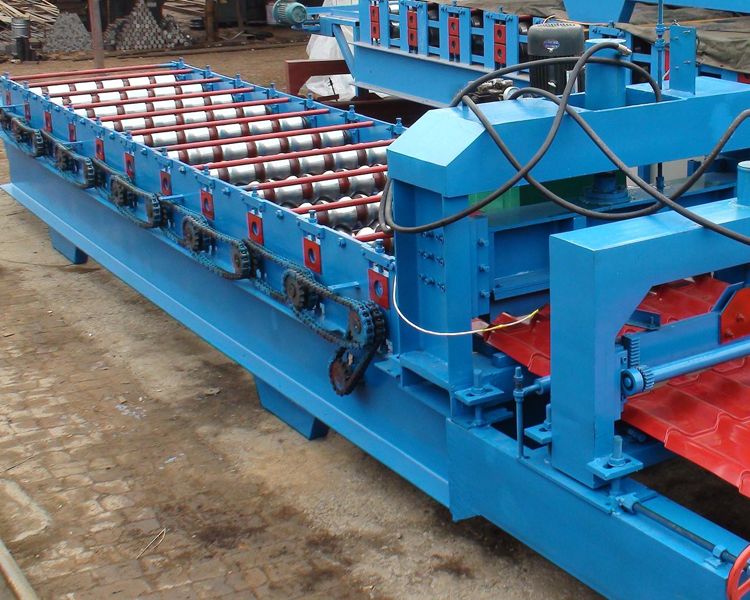

Glazed roof sheets made of glazed roof panel roll forming machines have the characteristics of light weight, high strength and durability.

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).