We normally continually offer you quite possibly the most conscientious buyer services, as well as the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Professional China Automatic Stainless Steel Scotch Brite-satin/no.4 Snow Coil To Coil Polishing And Grinding Machine, All prices depend upon the quantity of your order; the more you order, the more economical the price is. We also offer good OEM service to many famous brands.

We normally continually offer you quite possibly the most conscientious buyer services, as well as the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Coil To Coil Polishing Machine Of No.4, Coil To Coil Sanding Machine Line, Scotch Brite-satin Polishing Machine, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, complete meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

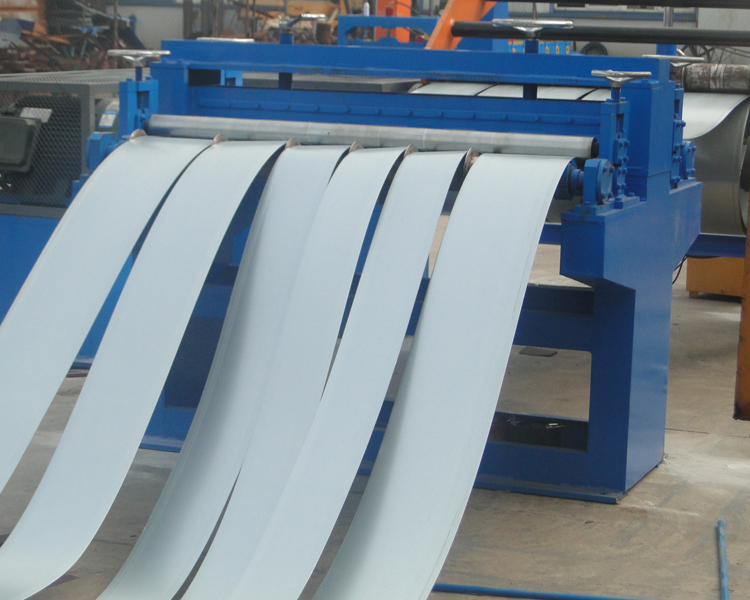

Slitting machine line cuts the metal coil into strips of various widths required, and then collects the strip into small rolls for use in the next process.

|

Slitting line machine parameters |

||

|

Raw Material (if the material is stainless steel, please tell in advance) |

1 | Material: carbon steel and others |

| 2 | The thickness of the material: 0.4mm-6mm. | |

| 3 | Width: 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm | |

| 4 | Input width: 600-1600mm | |

|

Hydraulic decoiler with car |

1 | The inner size: 450–610mm |

| 2 | The Max width: 1250mm | |

| 3 | The capacity: 15T 20Ton or more | |

|

Flatting and Cutting System |

1 | 2 shafts for feeding coil, 9 shafts for flatting |

| 2 | material of flatting: 42CrMo heat treated 50-52. | |

| 3 | hydraulic system. | |

| 4 | 2 sets cutting blade | |

| 5 | width of cutting: 600mm–1220mm. | |

| 6 | the material of blade mould: Gr12MoV | |

| 7 | power: 22KW Motor with ZQ650 Reducer | |

|

Slitting system |

1 | The width range: 200–1300mm |

| 2 | The precious of the width: ±1mm | |

| 3 | The speed of slitting: 25m/min | |

| 4 | The width can be change. | |

| 5 | Material of the slitting: Cr12MoV. | |

| 6 | Hardness of slitting blade: HRC5860. | |

| 7 | Slitting: 2~3mm 6 lines. | |

| 8 | Quantity of blades: 10 sets. | |

| 9 | Width of side scrap: 3-15mm | |

| 10 | The precious of side scrap: ±0.5mm | |

| 11 | Quantity of side scrap: 2 strips | |

| 12 | Power of the slitting: 37KW, 1000r/min, with ZQ750 Reducer. | |

|

Control System |

1 | Screen: 3.2inch button screen |

| 2 | PLC: Delta | |

|

Electrical collecting machine with car |

1 | Material inner: 550-650mm |

| 2 | Max Coil width: 1500mm | |

| 3 | Carrying capacity: 5T | |

| 4 | Automatic relax or collect | |

| 5 | Power: 22KW | |

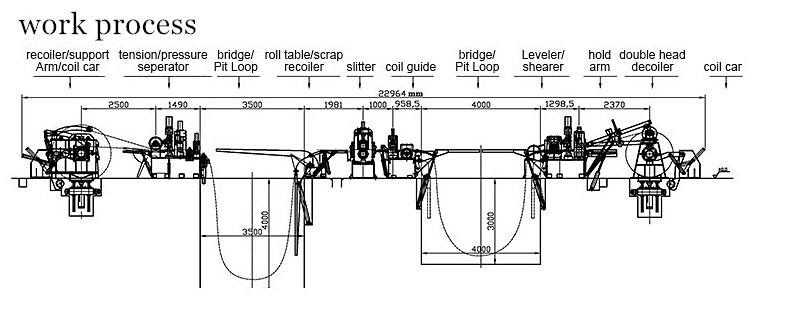

Working process

Decoiler —-flatting and cutting—slitting—–flatting and collecting

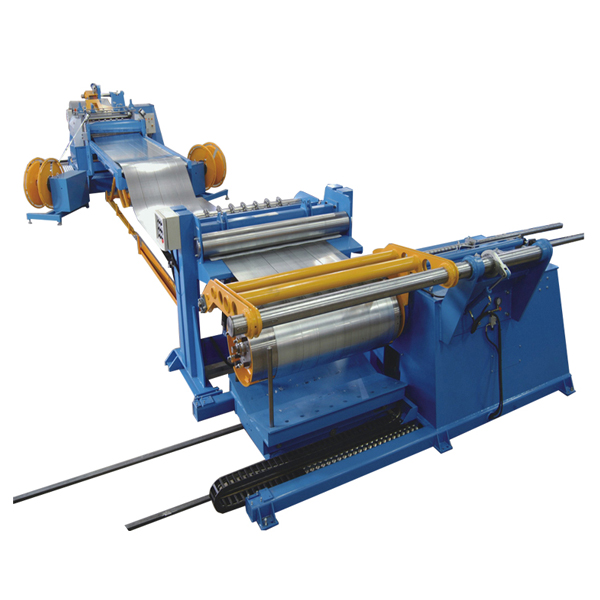

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.