PriceList for Sheet Guillotine Shearing Machine - Galvanized Curving Roof Machine – Haixing Industrial Detail:

|

Galvanized Curving Roof Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

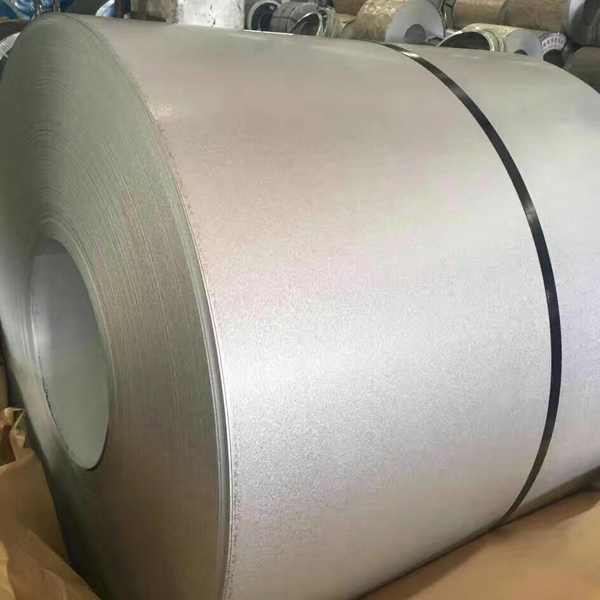

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

The advantages of galvanized curving roof machine:

1. Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2. Controlling by computer, PLC display, operation is easy, running is steady and reliable, endurable, maintenance-free.

3. We can make and designs will kinds of roll forming machine according to customer’s request.

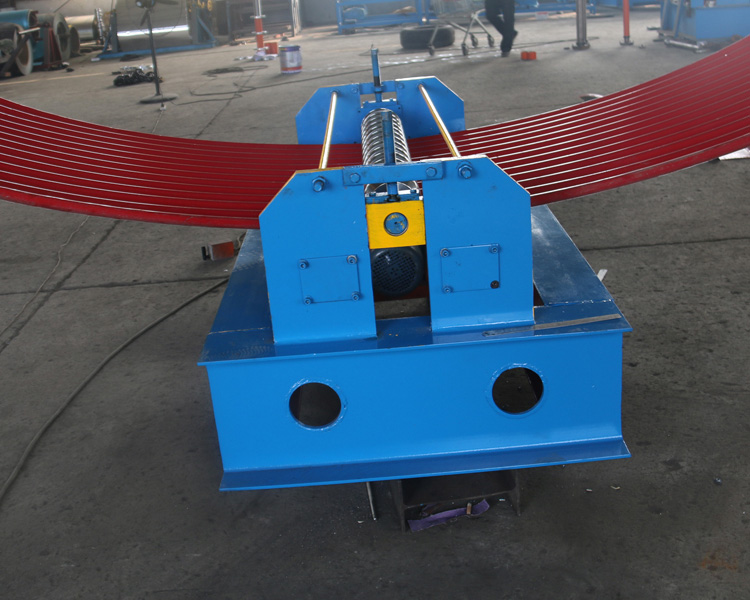

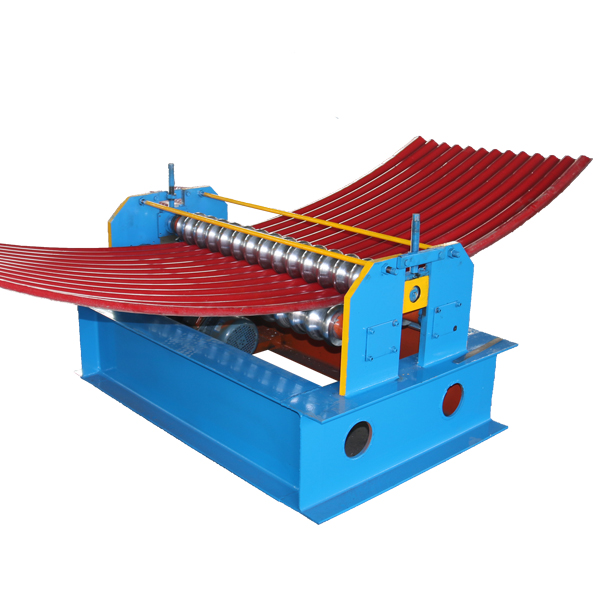

Machine photos:

Product detail pictures:

Related Product Guide:

Blackjack’s Rise And Fall Shows What Drives Customers Away | Steel Downpipe Roll Forming Machine

Mace’s Can of Ham brings party tricks to the City | Features | Ibr Roof Sheet Making Machine

PriceList for Sheet Guillotine Shearing Machine - Galvanized Curving Roof Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Factory wholesale Manufacturing Ridge Cap Roll ...

-

Discount Price Ppgi Ppgl - Metal Sheet Cut To ...

-

Hot sale Aluminum Roofing Sheet Roll Forming Ma...

-

Discountable price Press Bending Machine - Alu...

-

Super Lowest Price Metal Roofing Sheets Machine...

-

OEM Supply Pipe Roll Forming Machine - Alumini...