Gaining customer satisfaction is our company’s aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for PriceList for Roof Tiles Roll Forming Corrugation Machine, We’re searching forward to forming prosperous organization marriage with new shoppers during the around long run!

Gaining customer satisfaction is our company’s aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for Double Layer Roll Forming Machine, Roof Tiles Roll Forming Corrugation Machine, Roof Tiles Roll Forming Machine, The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. “XinGuangYang” HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

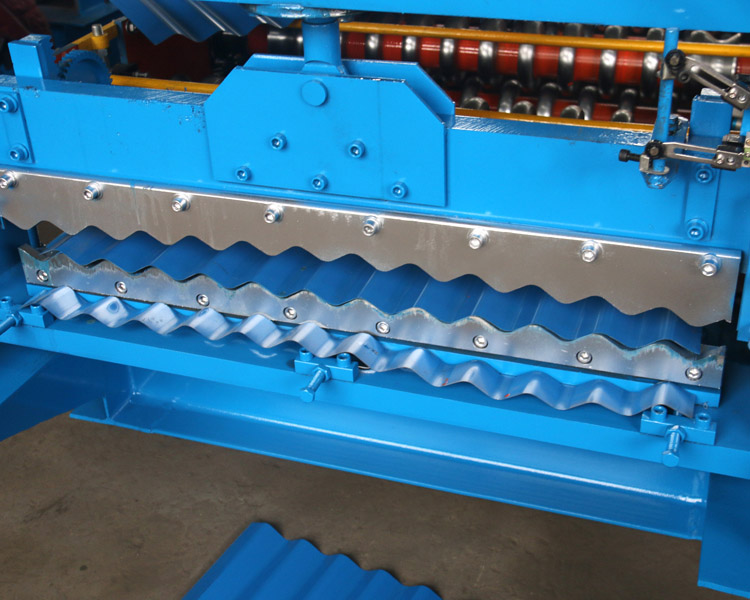

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Special Price for Different Types Trapezoid Iro...

-

China Cheap price Innovative Hydraulic Metal Sh...

-

Newly Arrival Aluminum Roofing Sheet Roll Formi...

-

China New Product Furring Channel Ceiling Keel ...

-

Short Lead Time for Omega Profile Roll Forming ...

-

Cheap PriceList for Following Type 1300mm Width...