PriceList for Pipe Channel Machine - Europe style Zinc Sheet Metal Bending Machine,Bending Machine For Doors – Haixing Industrial Detail:

We always follow the principle “Quality Very first, Prestige Supreme”. We have been fully committed to delivering our customers with competitively priced high-quality products and solutions, prompt delivery and experienced services for Europe style Zinc Sheet Metal Bending Machine,Bending Machine For Doors, We promise to try our greatest to deliver you with premium quality and efficient solutions.

We always follow the principle “Quality Very first, Prestige Supreme”. We have been fully committed to delivering our customers with competitively priced high-quality products and solutions, prompt delivery and experienced services for Bending Machine, Bending Machine For Doors, Zinc Sheet Metal Bending Machine, With the spirit of “high quality is our company’s life; good reputation is our root”, we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

|

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

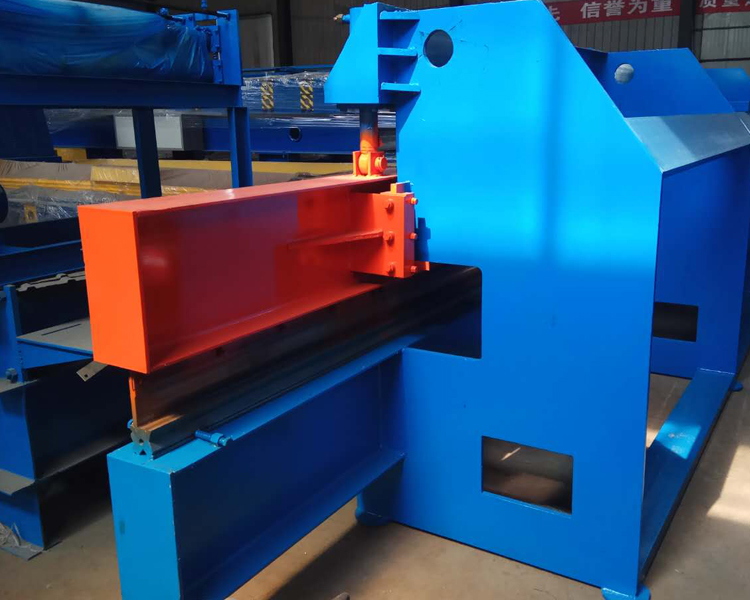

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

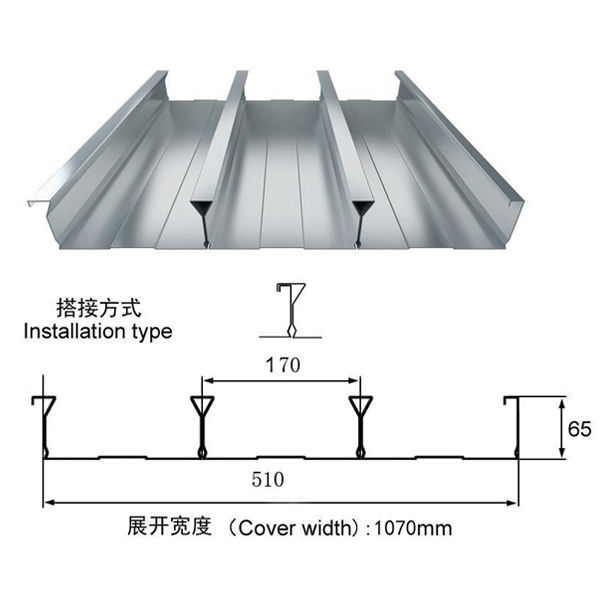

Fisker Brought its 161-MPH EMotion Sports Sedan with 400 Miles of Range to CES | Floor Deck Macking Machine

Facebook is hosting an online abuse summit with other tech leaders Engadget Engadget save share save share save share save share save share save share ear icon eye icon text file vr | Roof Sheet Curving Machine

PriceList for Pipe Channel Machine - Europe style Zinc Sheet Metal Bending Machine,Bending Machine For Doors – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

China Manufacturer for Cnc Shearing Machine - ...

-

Wholesale Price China Metal Deck Making Machine...

-

Chinese wholesale C Channel Purlin Forming Mach...

-

100% Original Factory Ceiling Keel Making Machi...

-

Cheapest Price Tile Floors Decking Roll Forming...

-

8 Year Exporter Metal Sheet Cut To Length Line ...