owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for PriceList for -end Low Roof Panel Ridge Cap Tile Machine, Your assistance is our eternal electrical power! Warmly welcome buyers at your home and abroad to go to our organization.

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for -end Roof Panel Ridge Cap Tile Machine, Low Roof Panel Ridge Cap Tile Machine, Roof Panel Ridge Cap Tile Machine, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products and solutions, reuse on the solution. We have Updated our catalog, which introduces our organization. n detail and covers the primary products we deliver at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

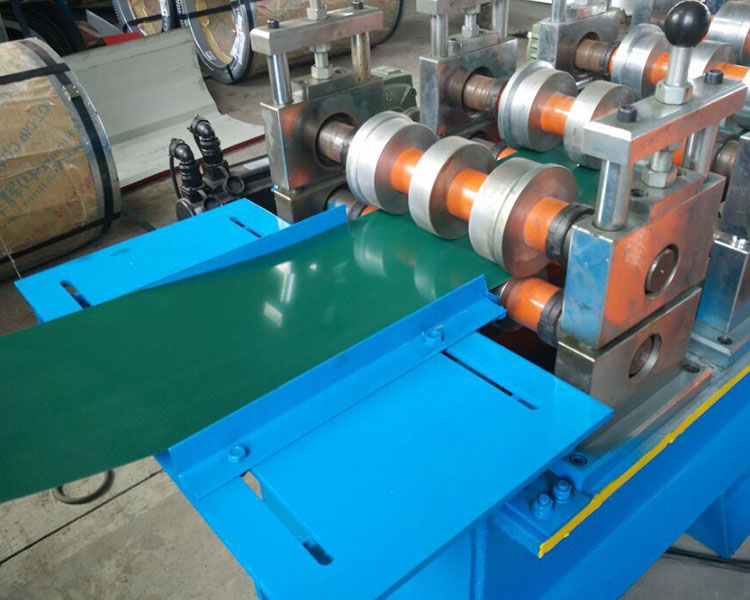

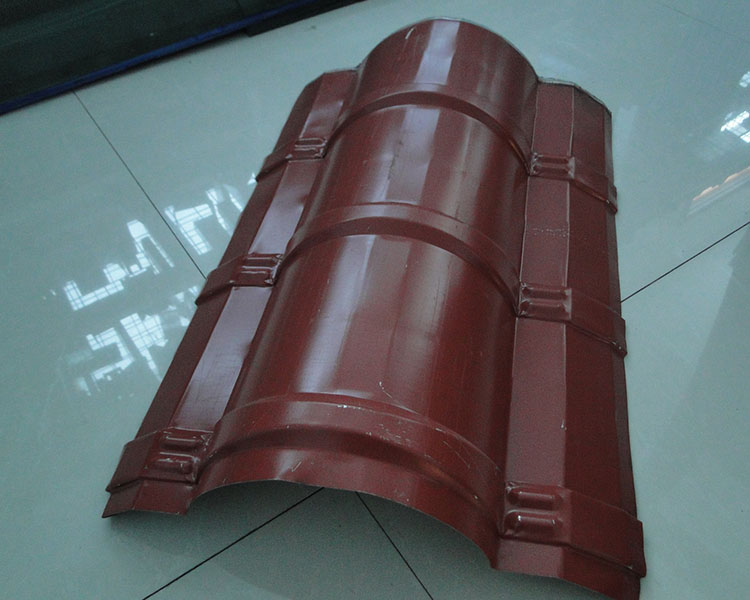

Roofing ridge cap cold roll forming machine is mainly used to produce the roof panel. The traditional ridges are made of glazed tiles, but have now been replaced by new ridge tiles. The color steel ridge tiles and aluminum-formed ridge tiles that are pressed out of roof ridge making machine are lighter, easier to install and less expensive.

|

Machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

Components of Galvanized Ridge Roofing Sheet/Cap Roll Forming Machine

1. Manual Decoiler…………………………………………….1 set

2. Feeding Guide……………………………………………….1 set

3. Main Roll Forming Machine……………………………1 set

4. Hydraulic Cutting Device………………………………..1 set

5. Hydraulic Station…………………………………………..1 set

6. PLC Computer Control…………………………………..1 set

7. Output Table…………………………………………………1 set

Machine details:

Package and shipment details:

The machines sold by Haixing Industrial Group Co., Ltd. use standard export packaging, as follows:

1*40 GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

We have a variety of machinery and production methods to meet the growing needs of our customers. Our different types of roll forming are easy to operate and highly efficient for Canada, Korea, Pussia, Netherlands, Suriname, Sri Lanka, Malaysia, Vietnam, Nigeria, Tanzania, India, Mongolia, Armenia, Kazakhstan, Vladivostok, Bolivia, Azerbaijan, etc.

-

Chinese wholesale Slitting Line Automatic Alumi...

-

Newly Arrival Galvanized Steel Door Frame Cold ...

-

Good Quality Galvanized Door Frame Roll Forming...

-

Cheapest Factory Ceiling T Grid Cross Suspended...

-

Hot New Products Galvanized Sheet Metal Roofing...

-

Hot sale Full Automatic Speed 60m/min Roll Form...