To constantly improve the management system by virtue of the rule of “sincerely, good faith and quality are the base of enterprise development”, we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for PriceList for China Dx Electric Curving Making Machine, We often concertrating on creating new creative solution to meet request from our customers everywhere in the planet. Sign up for us and let’s make driving safer and funnier with each other!

To constantly improve the management system by virtue of the rule of “sincerely, good faith and quality are the base of enterprise development”, we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for China Electric Curving Making Machine, Roof Making Machine, In order to meet our market demands, we now have paied more attention to the quality of our products and solutions and services. Now we can meet customers’ special requirements for special designs. We persistently develop our enterprise spirit “quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

Aluminium sheet curved roof panel roll forming machine parameters

| Main frame | Welded from 350mm H-beam. |

| Roller shaft diameter | 70mm, solid shaft with retaining pad |

| shaft material | 45# steel chrome 0.03mm |

| Transfer method | 1.0 inch chain |

| Medium plate thickness | 16mm |

| Main motor | 3kw, Siemens Bede Motor |

| Hydraulic power station | 4kw, gear pump: Shanghai Lichao |

| Cutter material | Cr12, heat treatment HR50-60 |

| Cutting method | Hydraulic four-column cutting |

| Length tolerance | ±2mm |

| PLC | High-precision computer control cabinet: Taiwan Delta; touch screen, frequency converter: Mitsubishi |

| Production speed | 1.5-3 m/min |

| Voltage | 380V, three-phase, 50 Hz |

| Feed width | 914mm or or according to customer requirements |

| Number of rows | 3 rows |

| Equipment size | 6500*1350*1400mm |

| Pressing mold material | Cr12 |

| Raw material thickness | 0.28~0.8mm |

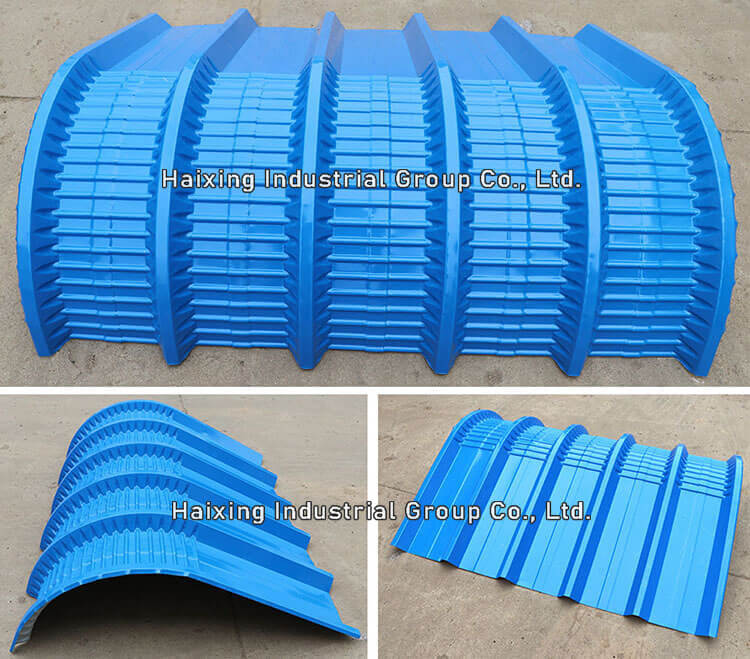

Aluminium sheet curved roof panel roll forming machine pictures

Packing & Shipping

a.The main body of aluminium sheet curving curved roof panel roll forming machine with water-proof plastic, then fixed to container by 8mm diameter steel wire and angle iron.

b.Rollers and shafts are covered with anti-rust oil.

c.PLC control system and motor pump are packed with waterproof paper and plastic film.

d.Spare parts in a carton box.

e.Manual decoiler was nude packing.

f.The output-table put into a carton box.

g.If the machine is too long, we will divide it into two parts and pack them in one package with steel wire.

h.Fit for ocean shipping.

-

1080mm design trapezoid roof tile making machine

-

building metal trapezoidal roof rool making mac...

-

C Light Steel Keel Roll Forming Machines

-

Color Steel Glazed Tiles Roof Panel Making Machine

-

10 Ton Hydraulic Decoiler With Coil Car

-

201 Steel Cold Roll Stainless Aluminum Coil

-

4 Meters Hydraulic Roof Sheet Bending Machine

-

6m Steel Bending Machine

-

762 Corrugated Roof Metal Sheet Roll Forming Ma...

-

988 Corrugated Roof Roll Forming Machine

-

Advanced Cnc Hydraulic Metal Sheet Shearing Mac...