Popular Design for Floor Deck Roll Forming Machines - OEM Customized Direct Machines Making Steel Door Galvanized Steel Roller Shutter Doors Shutter Door Frame Roll Forming Machine – Haixing Industrial Detail:

Bear “Customer initially, High quality first” in mind, we do the job closely with our customers and supply them with efficient and skilled providers for OEM Customized Direct Machines Making Steel Door Galvanized Steel Roller Shutter Doors Shutter Door Frame Roll Forming Machine, 1st business enterprise, we find out each other. Even further business enterprise, the trust is getting there. Our enterprise always at your services at any time.

Bear “Customer initially, High quality first” in mind, we do the job closely with our customers and supply them with efficient and skilled providers for Galvanized Steel Roller Shutter Doors, Roller Shutter Door, Shutter Door Frame Roll Forming Machine, We now have our own registered brand and our company is developing rapidly owing to high quality goods, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

|

Steel profile door frame roll forming machine parameters |

||

| 1 | Material width | 3 sizes. Waiting for buyer exactly profile |

| 2 | How to adjust size | Option : by PLC (It can be adjust by PLC and also in hand wheel) One side fixed and the other is adjustable by manual or PLC |

| 3 | Base frame | base frame 30 mm thick steel plate process the surface on CNC planer to keep it leveling and drill bolts and key slot by CNC |

| 4 | Rolling Speed | 12-15m/min(not include cutting time) |

| 5 | Rolling Thickness | 1.2-2.0mm |

| 6 | Material | GI or metal |

| 7 | Control System | PLC (Panasonic) as list in the note |

| 8 | decoiler | 3 Ton manual decoiler |

| 9 | Leveling | Up in 3 roller, down in 4 roller |

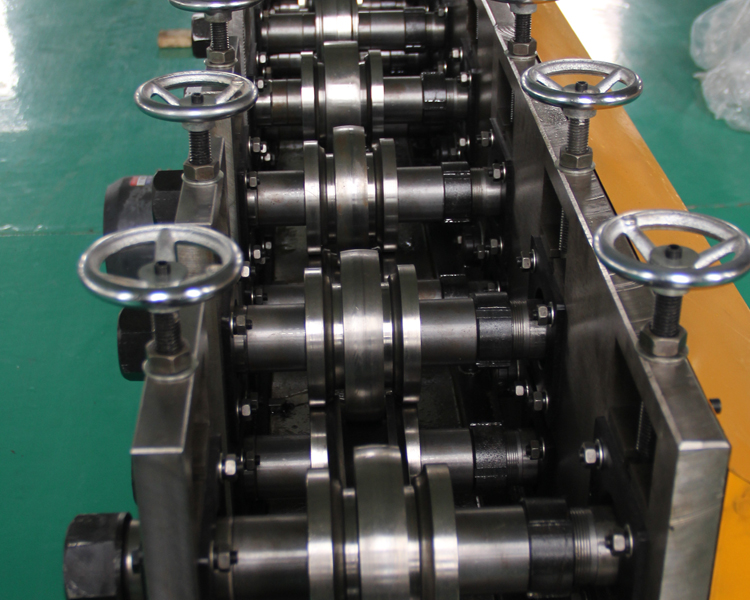

| 10 | Roller Stations | About 20 stations |

| 11 | Roller Material | Gcr15, coated with chrome HRC58-62 degree |

| 12 | Shaft Material and DIA | ¢70mm, material is 45# forge steel |

| 13 | Maim Motor Power | 11kw brake motor |

| 14 | Hydraulic Station Power | 5.5kw |

| 15 | Hydraulic Pressure | 20Mpa |

| 16 | Capacity of tonnage for punching | 22Tons |

| 17 | Hydraulic pump brand | Lichao |

| 18 | Cutting | Hydraulic post-cutting for cut end product |

| 19 | Extra cutter | One more cutter for each profile |

| 20 | Material Of Cutting | Cr12Mov quenching 58-62ºC |

| 21 | Electric Source | 380V, 60HZ,3 phase |

| 22 | Way Of Drive | 1.2 inch single chain |

| 23 | Color Of The Machine | Yellow and blue |

| 24 | Machine Type | Iron Cast |

| 25 | Emergency switch | In main machine and control panel all have emergency switch for forbid any urgently accident. |

| 26 | Protect cover | Complete mobile safety cover from roll forming to the cutter. |

| 27 | Size of the machine | L*W*H 12m*1.2m*1.2m |

| 28 | Container Need | 1 x40 feet (base on final) |

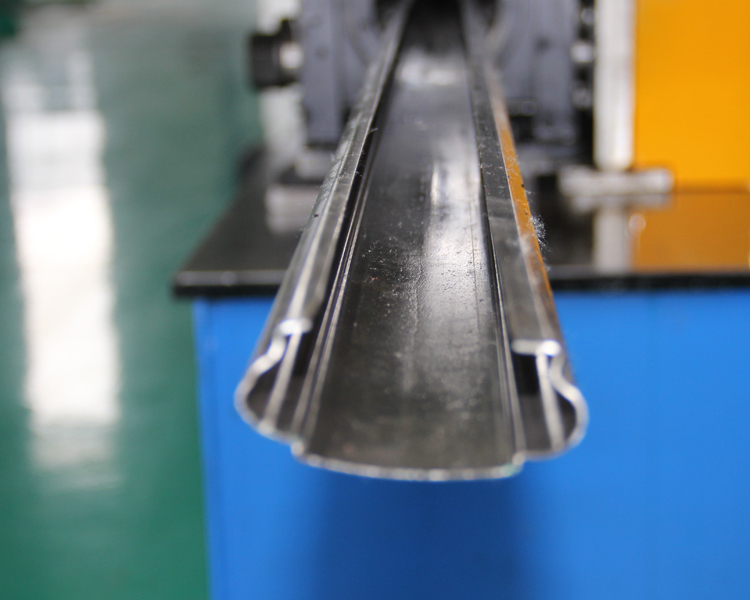

The steel door frame roll forming machine is a complete product line. After roll forming by our production line, we could make very smooth and beautiful steel door frame without any scratch on surface.

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

The legacy of PlayStation creator Ken Kutaragi, in 24 stories | Decoiler In Color Coating Line

Across the Fence with MACV-SOG: You shot me three times | Decoiler In Color Coating Line

Popular Design for Floor Deck Roll Forming Machines - OEM Customized Direct Machines Making Steel Door Galvanized Steel Roller Shutter Doors Shutter Door Frame Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

18 Years Factory Roof Panel Machine - Manual d...

-

High reputation Micro Slitter Machine - Stone ...

-

2017 wholesale price High Performance Down Pipe...

-

Hot Selling for Roof Making Machine - C channe...

-

Best Price on Trapezoidal Roofing Roll Forming ...

-

Factory Free sample Steel Sheet Floor Deck Roll...