We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for Original Factory China Light Keel Wall Angle Making Machine, We believe in quality over quantity. Before export of the hair there is strict quality control check during treatment as per international quality standards.

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for China Roll Forming Machine, Metal Forming Machine, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our products. Customers’ benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

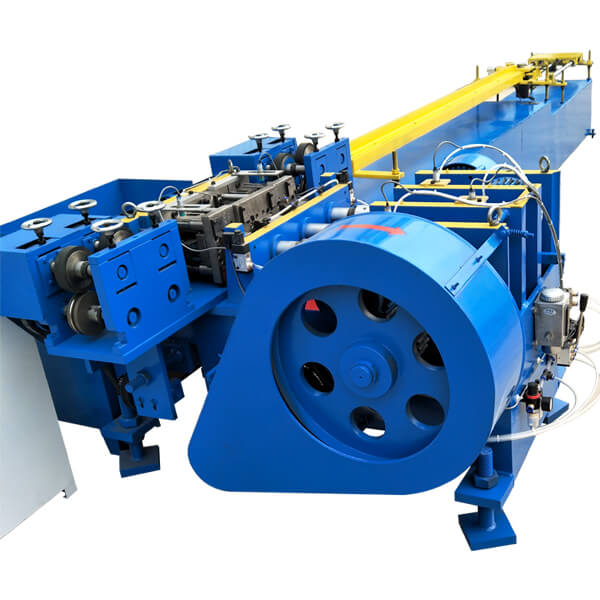

Light Gauge Steel Stud Track Framing Machine Quick Details

| Material | Colored steel sheet, galvanized steel sheet, aluminum sheet |

| Thickness of coil sheet | 1.0-2.0mm |

| Efficiency width | 25/30mm |

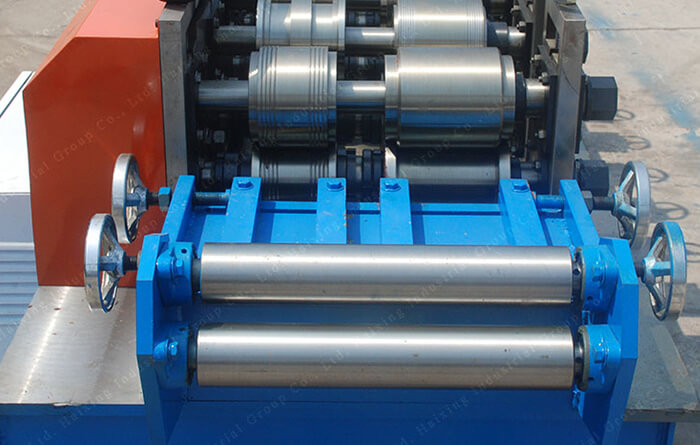

| Roller material | High grade NO. 45 forged steel with 0.05mm hard chrome plating |

| Shaft material | High grade NO. 45 carbon wrought steel |

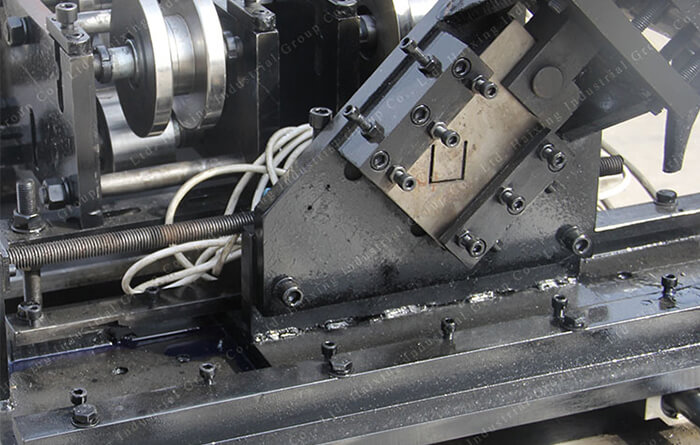

| Cutting blade | Cr12 mould steel with quenched treatment |

| Diameter of shaft | 70mm or as your requirement |

| Main frame | 300 H steel |

| Forming steps | 16 stations |

| Productivity | 30-35m/min |

| Hydraulic station power | 5.5 KW |

| Hydraulic pressure | 10-12MPa |

| Appearance size | 7700mm*1500mm*1500mm |

| Hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirement |

| Cut Mode | Hydraulic forming after cutting off |

| Cutter materia | Cr12 Heat Treatment |

| Electronic control system | PLC, Touch Screen, Encoding counter |

| Color | Blue, green or yellow or as your requirement |

| Rolling material | 45# steel,roller surfaces polishing, hard plating |

Light Gauge Steel Stud Track Framing Machine Details

Installation and training services:

A. If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

B. Without visiting, we will send you user manual and video to teach you to install and operate.

C. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

Light Steel Keel Forming Machine Advantage

1. Good quality: We have a professional designer and experienced engineer team. And the raw material and accessories we use are good.

2.Good service: we provide technical support for the whole life of our machines.

FAQ

Q: Are you a trading company or a factory?

A: We are factory with the professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: How long does it take to produce the machine?

A: Generally speaking, the machine can be completed within 20~45 working days. But if you need machines urgently, we can do our best to save you time.