One of Hottest for Down Pipe Cold Roll Forming Machine - Standing Seam Roof Panel Machine – Haixing Industrial Detail:

The roof sheet made by standing seam roof panel machine is a new type of roofing panel. In Haixing Industrial Group Co., Ltd., standing seam roof panel machine adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production.

Machine parameters

| 1 | Thickness | 0.3-0.8mm |

| 2 | Coli material | GI |

| 3 | The bearing capacity of manual decoiler | 6.5 tons |

| 4 | shaft material | 45#steel |

| 5 | Out diameter | Customized |

| 6 | numbers of forming steps | Customized |

| 7 | transmission | chain transmission |

| 8 | Forming speed | 8-12m/min |

| 9 | main motor power | 3kw |

| 10 | voltage | 380V50HZ Three-phase or as required |

| 11 | dimension | 7*1.3*1.3 |

| 12 | cutting | hydraulic cutting |

| 13 | blade material | Cr12 steel with quenched treated 60℃-62℃ |

| 14 | control system | PLC(Delta) |

| 15 | length tolerance | ±1mm |

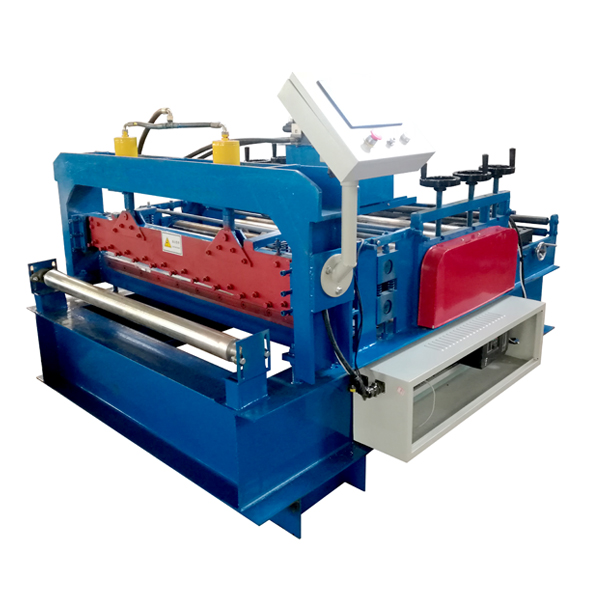

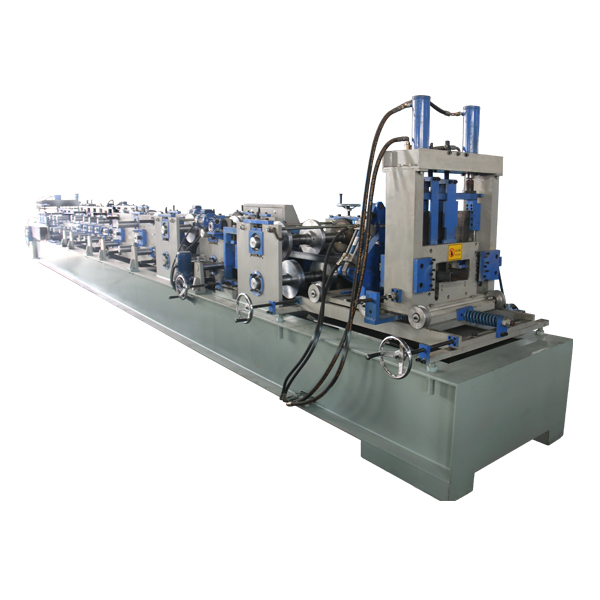

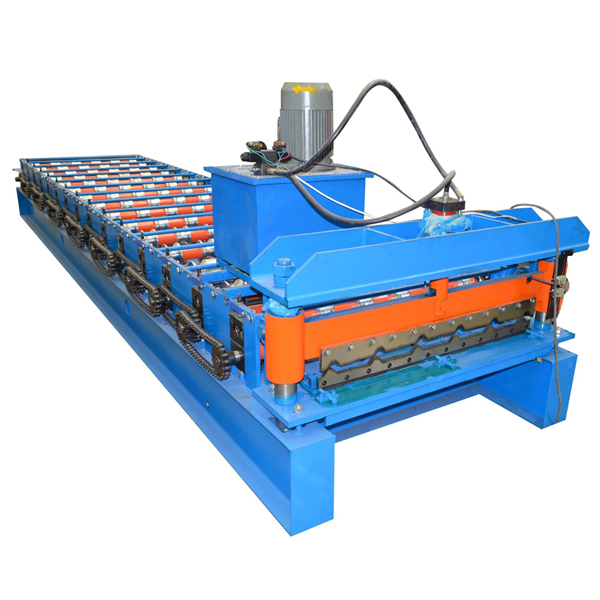

Machine photos:

The machines sold by Haixing Industrial Group Co., Ltd. use standard export packaging, as follows:

1*40GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

Product detail pictures:

Related Product Guide:

Enercon’s EP3 vision takes shape | Roof Sheet Curving Machine

PHOTO: Bear climbs up to 2nd floor deck to eat bird seed | Decoiler In Color Coating Line

One of Hottest for Down Pipe Cold Roll Forming Machine - Standing Seam Roof Panel Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Good Quality Roofing Curve Machine - Factory S...

-

Wholesale Dealers of Slitter Rewinder-Automatic...

-

Wholesale Small Roof Tile Machine - Roof Roll ...

-

Well-designed Metal Door Frame Cold Roll Formin...

-

Low price for Standing Seam Roof Sheet Roll For...

-

2017 wholesale price Shear Machine - Aluminum ...