One of Hottest for Deck Sheet Roll Forming Machine - New Fashion Design for Colored Galvanized Ibr Sheet Metal Shed Roof Sheeting – Haixing Industrial Detail:

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for New Fashion Design for Colored Galvanized Ibr Sheet Metal Shed Roof Sheeting, We play a leading role in supplying clients with high-quality items very good provider and competitive price ranges.

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for Colored Metal Sheeting, Galvanized Roofing Sheet, Ibr Sheet Metal Shed Roof Sheeting, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create”the reputable international brand of nylon monofilaments”, and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

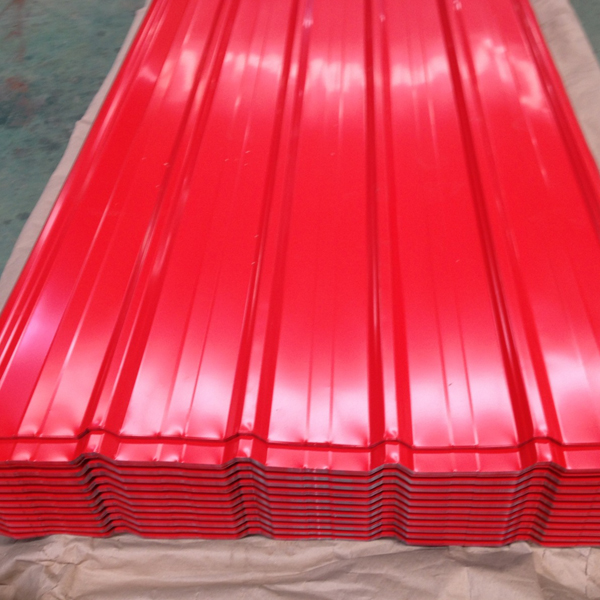

IBR roof sheets made of IBR roof panel roll forming machines generally refers to a profiled tile of an effective width of 686.

|

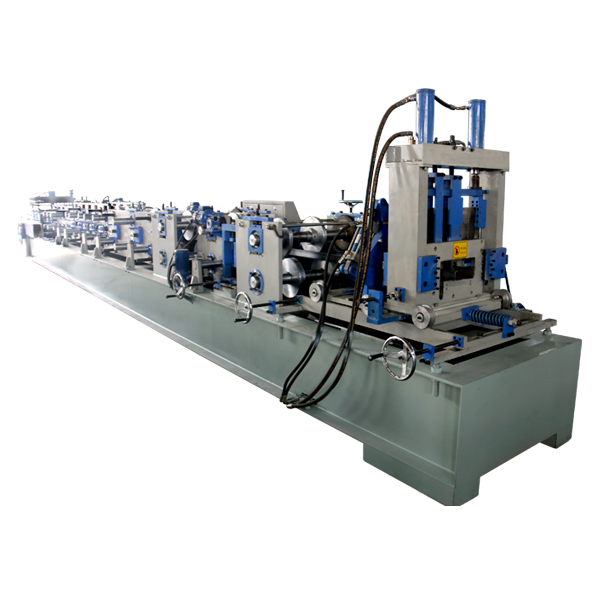

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

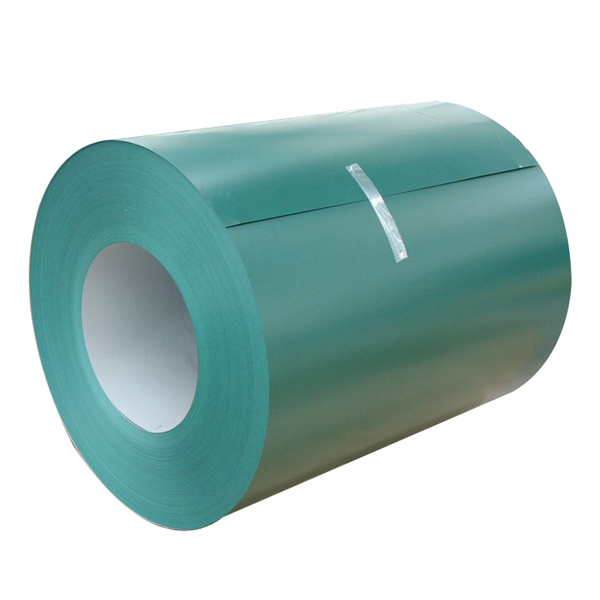

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm or 940mm |

| 12 | Effective width | 686mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

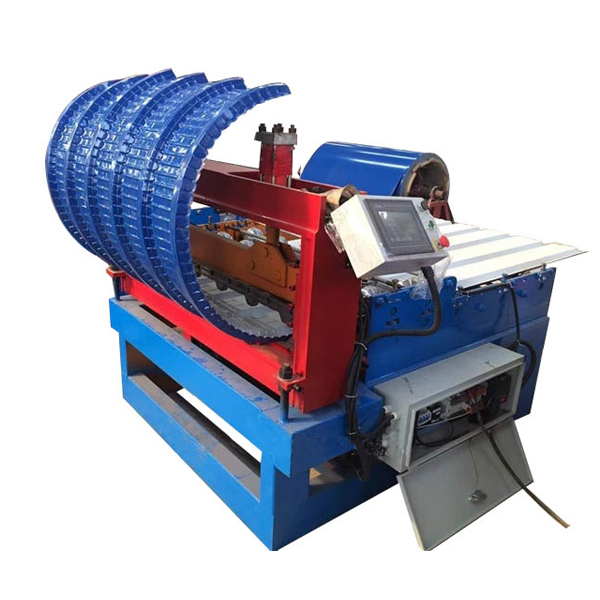

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Packaging Details:

1. machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Burning Out: What Really Happens Inside a Crematorium PM_Logo PM_Logo | Ibr Roof Sheet Making Machine

‘Call of Duty: Black Ops 4’ Zombies Voyage of Despair Easter Egg Guide & Walkthrough | Ibr Roof Sheet Making Machine

One of Hottest for Deck Sheet Roll Forming Machine - New Fashion Design for Colored Galvanized Ibr Sheet Metal Shed Roof Sheeting – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Factory Cheap Roofing Ridge Cap Cold Roll Formi...

-

Good Quality Sandwich Panel Forming Machinery -...

-

Good User Reputation for Cnc Roller Bending Mac...

-

2017 Good Quality Roofing Sheets Machine - Roo...

-

2017 wholesale price Sandwich Panel Machine Pri...

-

Reliable Supplier Stationary Welding Fume Extra...