We generally stick to the theory “Quality Very first, Prestige Supreme”. We’ve been fully committed to furnishing our shoppers with competitively priced high quality solutions, prompt delivery and expert services for OEM/ODM Supplier Building Material Aluminum Shutter Door Roll Forming Machine, In addition, we would properly tutorial the purchasers about the application techniques to adopt our items plus the way to select appropriate materials.

We generally stick to the theory “Quality Very first, Prestige Supreme”. We’ve been fully committed to furnishing our shoppers with competitively priced high quality solutions, prompt delivery and expert services for Aluminum Shutter Door Roll Forming Machine, Shutter Door Forming Machine, Shutter Door Roll Forming Machine, Due to good quality and reasonable prices, our products and solutions have been exported to more than 10 countries and regions. We’re looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

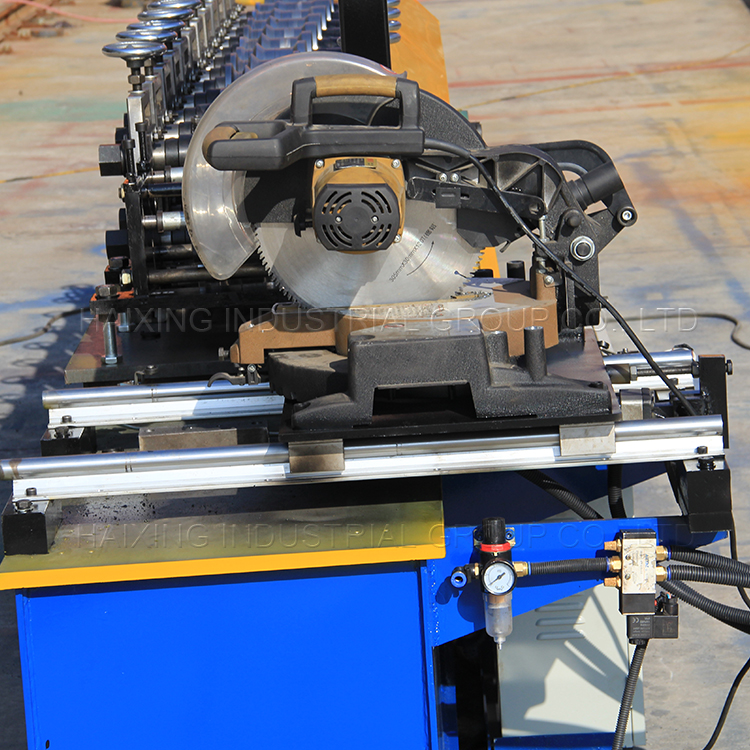

Roller shutter door forming machine flying saw cutting parameters

| 1 | Uncoiler | 3tons manual uncoiler |

| 2 | Feeding guide | 2 roller feeding guide |

| 3 | Forming rollers | 14 station rollers |

| 4 | Roller material | 50mm diameter cr12 steel, with twice CNC precise process |

| 5 | Forming body | 100mm x 80mm square pipe with 3.5mm |

| 6 | Forming body outside | With 16mm steel plate welded |

| 7 | Transmission | Gear transmission |

| 8 | Raw material | Galvanized steel, galvalume steel, color steel coil |

| 9 | Raw material thick range | 0.5mm to 1.2mm |

| 10 | Unloading support | 2 pieces 3meter |

| 11 | Main motor | 3KW/4KW |

| 12 | Pump motor | 3KW/4KW |

| 13 | PLC control system | Automatic control system, language: English, Spanish, Russian and so on. |

| 14 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan. Other elements are from famous suppliers of China. |

| 15 | Cutter blades | Cr12 mold steel with quenched treatment. |

| 16 | Factory area | The machine is the 7m length and 2m width, and output sheet according to the customer the longest sheet to calculate |

| 17 | Warrant time | 14 months |

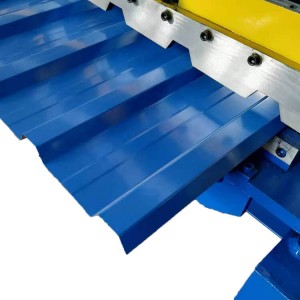

Machine pictures:

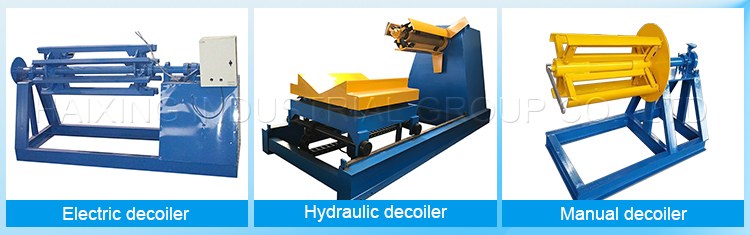

Decoilers

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.

-

Good quality Light keel pallet rack roll formin...

-

wall sheet metal roof panel roll forming machine

-

Factory directly Roof Tile Colored Glaze Steel ...

-

Rapid Delivery for Color Coated Coil Difference...

-

CE Certificate Colored Steel Roof Panel Sheet R...

-

2018 Latest Design Omega Profile Roll Forming M...