So as to give you ease and enlarge our company, we also have inspectors in QC Team and assure you our greatest support and product or service for OEM/ODM Manufacturer Trapezoidal Sheet Roof Tile Roll Forming Machine For Production Line, Thanks for taking your worthwhile time to visit us and sit up for have a nice cooperation along with you.

So as to give you ease and enlarge our company, we also have inspectors in QC Team and assure you our greatest support and product or service for Cold Roll Forming Machine, Roll Forming Machine, Trapezoidal Sheet Roof Tile Roll Forming Machine For Production Line, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

This type of trapezoidal roofing roll forming machine is very popular in Georgia, and its color steel tile has a good quality and beautiful appearance. It is a very worthwhile roll forming machine.

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

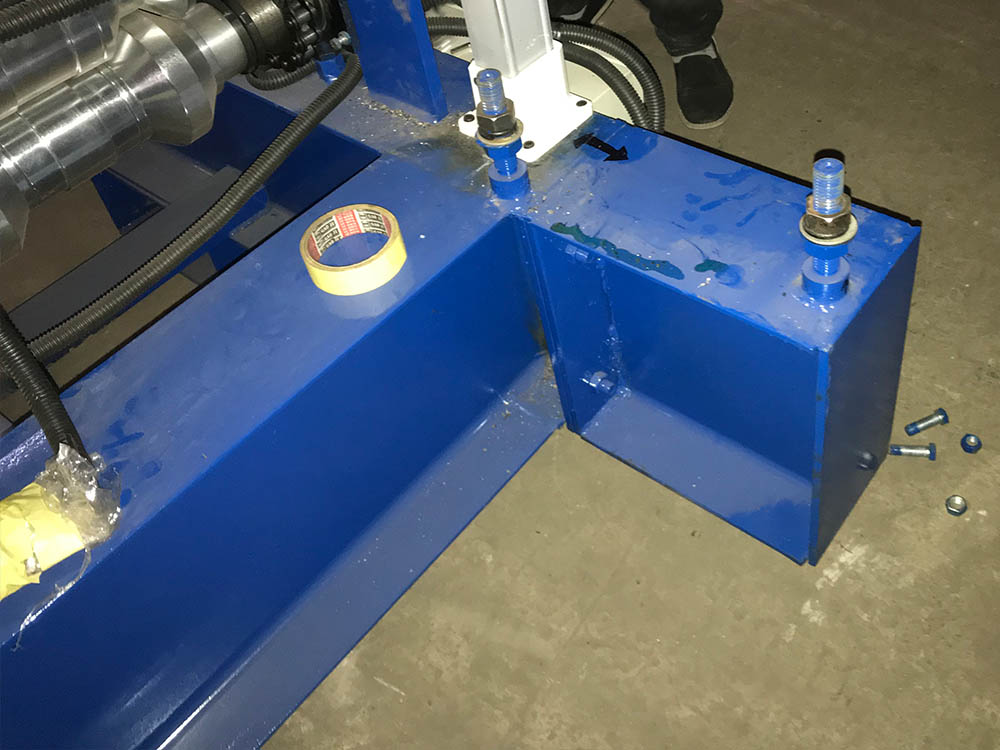

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine details

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

The advantages of C8 trapezoidal roofing roll forming machine:

1.Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2.Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable,maintenance-free.

3.We can make and design will kinds of roll forming machine according to customer’s request.