It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We’re seeking forward in your check out for joint development for OEM/ODM Manufacturer China Roofing Galvanized Aluminum Corrugated Metal Corrugated Roofing Sheet Machine, We honor our core principal of Honesty in company, priority in service and will do our best to provide our buyers with high-quality products and solutions and great support.

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We’re seeking forward in your check out for joint development for China Wall Panel, Roll Forming, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to deliver more quality items and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

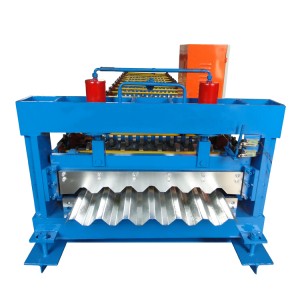

Parameters of double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Machine photos

Components of double layer corrugated roof sheet making machine

| No. | Name | Unit | Quantity |

| 1 | Manual decoiler | Set | 1 |

| 2 | Main forming machine | Set | 1 |

| 3 | PLC control system | Set | 1 |

| 4 | Hydraulic pump station | Set | 1 |

| 5 | Post cut | Set | 1 |

| 6 | Electric motor | Set | 1 |

| 7 | Output table | Set | 1 |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our company owned professional design team, we can design different profile according customer’s demands.

Why choose us ?

Professional:

With 10 years’ professional manufacturing experience in roll forming machinery;

Professional production line,well -trained workers,strict QC standard.