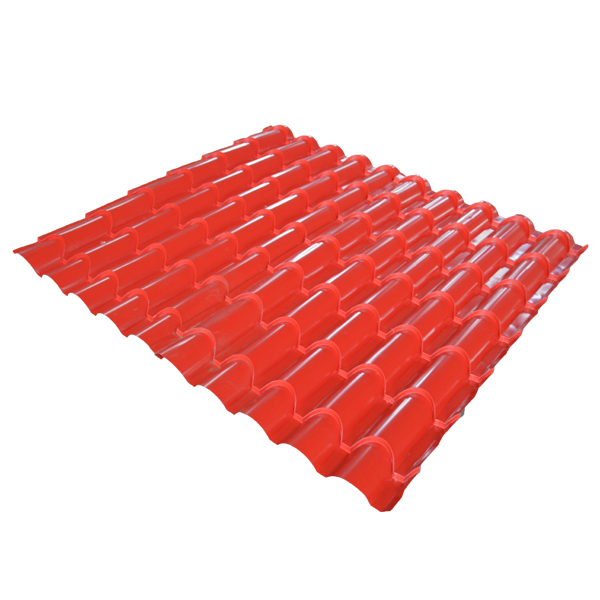

OEM/ODM Factory Arched Roof Tile Making Machine - Automatic Metal Floor Deck Roll Forming Machine – Haixing Industrial Detail:

|

Automatic metal floor deck roll forming machine parameters |

||

|

Feeding platform |

1 | Frame structure: steel plate welded |

| 2 | roller flatting system and pre-hand cutting system | |

| 3 | Advantage: not scratch the surface of metal plate | |

|

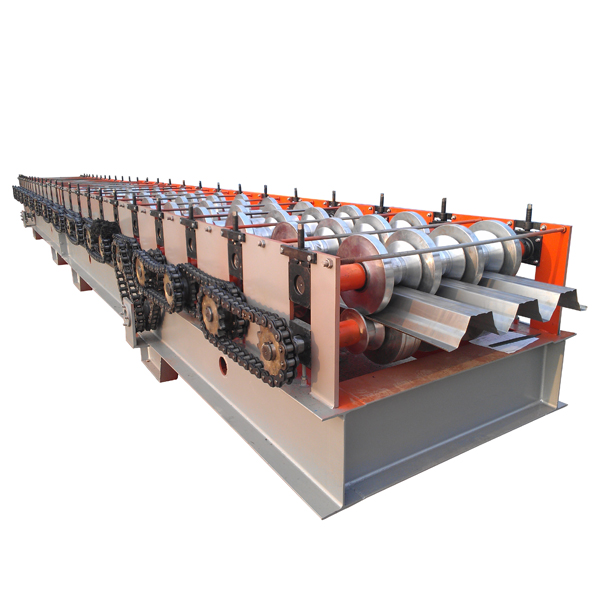

Roll forming M/C |

1 | Machine weight: 13 tons |

| 2 | Installation dimensions: 1500*1800*1500mm | |

| 3 | Machine under frame: steel 400 H-beam | |

| 4 | Sidewall: 45# steel plates | |

| 5 | Roller stations: 28 rows | |

| 6 | Shaft diameter: 85mm | |

| 7 | Side wall plate: 24mm | |

| 8 | Main shaft material: 45# steel with finish turning | |

| 9 | Roller material: 45# forging steel with chromium plate | |

| 10 | Chromium plate thickness: 0.05mm | |

| 11 | Motor power: 15kW*2, brand Siemens | |

| 12 | Reducer type: 2-8# gear speed reducer-Shanghai, China | |

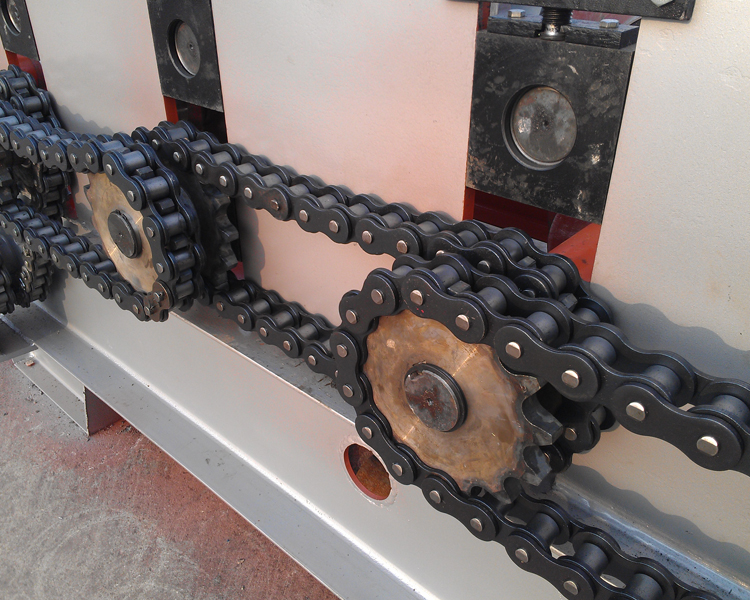

| 13 | Chain wheel and cycle chain: 1.2-inch | |

| 14 | Production line speed: 10-12m/minutes | |

|

PLC control system |

1 |

Functions: adapts quantity cutting system, length of roof sheet can be set on the computer |

| 2 | Tolerance: within 1.0mm | |

| 3 |

Frequency converter: Delta |

|

| 4 |

PLC is Siemens |

|

| 5 |

Encoder: Omron |

|

| 6 |

Touchscreen: Delta |

|

| 7 |

Voltage standard: 3 phases 380V/50Hz or according to customer’s need |

|

| 8 |

Pressing die material: Cr12 |

|

|

Hydraulic pressing device |

1 |

Quenched treatment 58 to 62ºC |

| 2 |

Length tolerance: ±2mm |

|

| 3 |

Pump station motor: 5.5kW, LICHAO, Shanghai |

|

| 4 |

Hydraulic oil: 40# |

|

|

Hydraulic cutting device |

1 |

Functions: adapts electric drive and automatic location system to decide the dimension and cut the target |

| 2 |

Working method: stop to post then post to cut |

|

| 3 |

Cutting mold material: Cr12 |

|

| 4 |

Quenched treatment 58 to 62°C |

|

| 5 |

Length tolerance: ±2mm |

|

| 6 |

Pump station motor: 5.5kW, LICHAO, Shanghai |

|

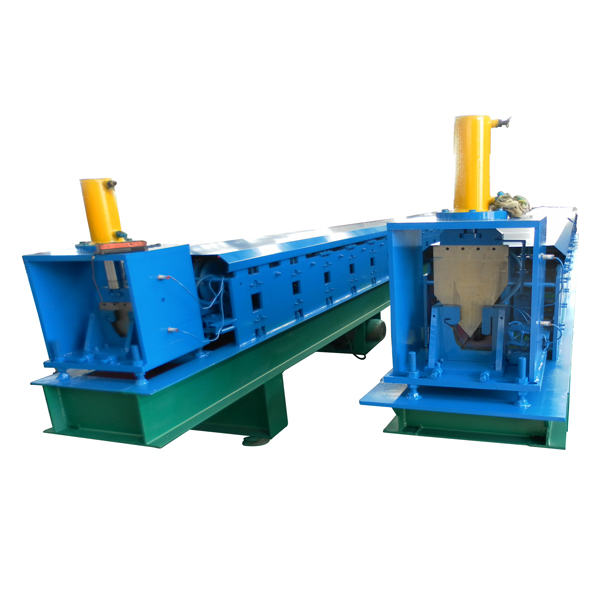

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Symphony of the Seas: Royal Caribbean takes delivery of cruise giant. | Floor Deck Macking Machine

Carnival Horizon: Giant new cruise ship debuts in Miami | Floor Deck Macking Machine

OEM/ODM Factory Arched Roof Tile Making Machine - Automatic Metal Floor Deck Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Reliable Supplier Portable Hydraulic Bending Ma...

-

Special Price for Decking Floor Plate Making Ma...

-

Factory wholesale T Grid Ceiling Machinery - T...

-

Factory directly Steel Plates Metal Roof - Rai...

-

Trending Products Double Deck Roll Forming Mach...

-

2017 wholesale price Automatic Roll Slitting Ma...